How to Choose the Best Steel for Molds and Dies in 2025

Choosing the right steel for molds and dies is crucial for achieving optimal performance and longevity. In 2025, you must consider several key factors that influence your choice of mould steel. These include advancements in technology, production demands, and material properties. Suitable steels for molds tools and die exhibit essential characteristics such as wear resistance, toughness, hardness, corrosion resistance, machinability, and dimensional stability. Understanding these properties will help you make informed decisions for your projects.

Key Takeaways

Picking the right steel for molds and dies is very important. Look at features like strength, wear resistance, and heat transfer.

Choose pre-hardened steel for faster production. It saves time and cuts costs because it is ready for machining without extra heating.

Check the specific needs of your project. Different methods like injection molding and die casting need different steels for the best results.

Keep up with new steel alloys and manufacturing methods. New ideas can make your molds work better and last longer.

Regular care and good cooling can greatly increase the life of your molds. Use high-quality steel to reduce wear and tear.

Key Requirements for Mold Steel

When selecting steel for molds and dies, you must prioritize several key requirements. These factors significantly impact the performance and longevity of your molds.

Strength

Strength is a critical property for mold steel. You need to ensure that the steel can withstand various stresses during production. Consider the following aspects of strength:

Hardness: This property ensures long-term use without deformation.

Toughness: Toughness prevents breaking or chipping under sudden loads.

Wear Resistance: Good wear resistance maintains surface smoothness during production cycles.

Corrosion Resistance: This protects against rust and damage in humid environments.

Thermal Conductivity: Effective thermal conductivity ensures even heat distribution during processes.

Polishability: High polishability guarantees a quality surface finish.

Dimensional Stability: Dimensional stability prevents warping or shrinking during use.

These factors contribute to the overall strength of the steel, making it suitable for demanding applications.

Wear Resistance

Wear resistance is another essential requirement for mold steel. You want materials that can endure the friction and abrasion that occur during production. High wear resistance helps maintain the mold's shape and functionality over time. For instance, tool steels like H-13 and P-20 are known for their excellent wear properties. They provide the durability needed for high-volume production without frequent replacements.

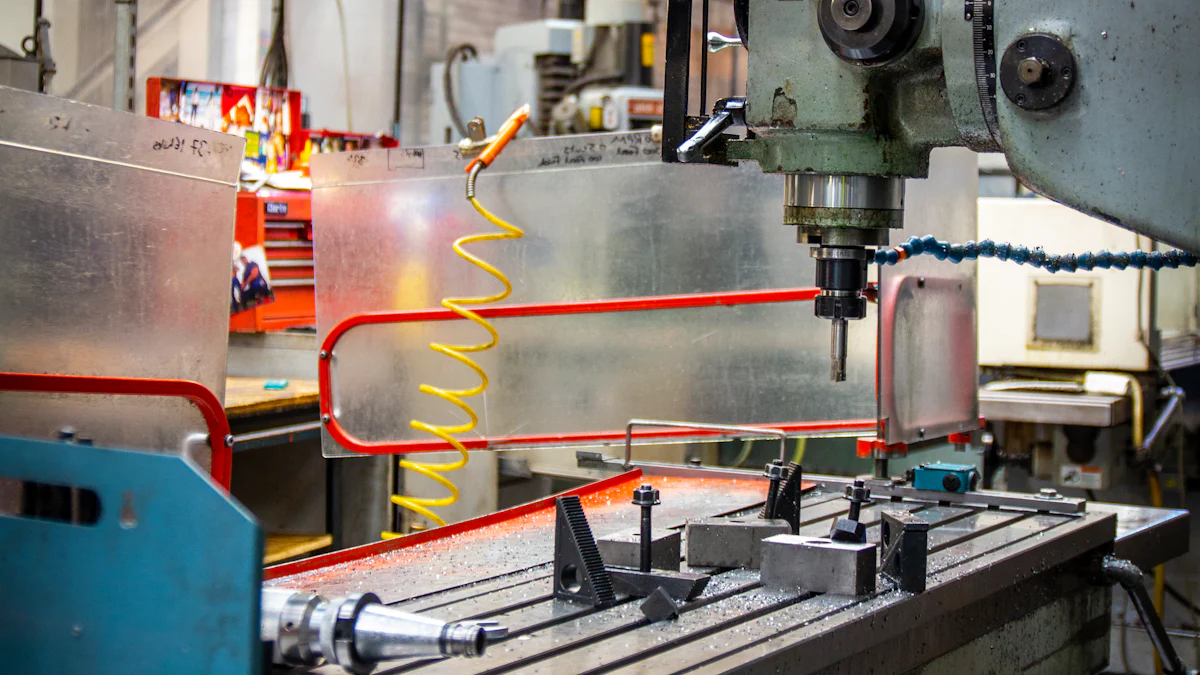

Machinability

Machinability is crucial when working with mold steel. You should prioritize pre-hardened steel with good machinability. This choice ensures effective machining while extending the mold's service life. Low hardness steel can lead to challenges in maintaining mold accuracy. Therefore, using hardened tool steel that balances machinability and durability is advisable. This approach allows you to achieve precise dimensions and high-quality finishes in your molds.

By focusing on these key requirements, you can select the best steel for your molds and dies, ensuring optimal performance and longevity.

Thermal Conductivity

Thermal conductivity plays a vital role in the performance of mold steel. It refers to the ability of a material to conduct heat. When you choose steel for molds and dies, consider how well it can manage heat during production processes. Here are some key points to keep in mind:

Heat Distribution: Good thermal conductivity ensures even heat distribution across the mold. This uniformity helps prevent hot spots that can lead to warping or cracking.

Cooling Efficiency: Efficient cooling reduces cycle times in production. When the mold cools quickly, you can increase your output without sacrificing quality.

Material Selection: Different steels have varying thermal conductivity levels. For example, tool steels like H-13 offer excellent thermal properties, making them suitable for high-performance applications.

Impact on Surface Finish: Proper heat management contributes to a better surface finish. When the mold maintains consistent temperatures, it helps achieve smoother surfaces on the final product.

Tip: Always check the thermal conductivity ratings of the steel you consider. This information can guide you in selecting the right material for your specific application.

Types of Steel for Molds and Dies

When selecting steel for molds and dies, you will encounter two primary categories: alloy steels and general-purpose steels. Each type has unique properties that make it suitable for specific applications.

Alloy Steels

Alloy steels are popular choices for molds and dies due to their enhanced strength and durability. You can achieve these properties by adding elements like chromium, nickel, and molybdenum. This combination makes alloy steel ideal for high load-bearing tasks. Additionally, alloy steels exhibit excellent corrosion resistance, especially in harsh environments. They maintain their properties at high temperatures, making them suitable for applications like engine components. Their versatility allows you to tailor them to specific needs, making them useful across various industries. Furthermore, alloy steel is cost-effective compared to other specialized materials, providing a balance of affordability and superior mechanical properties.

Tool Steel

Tool steel is a subset of alloy steel specifically designed for making tools and dies. It offers high hardness and wear resistance, which are essential for maintaining the shape and functionality of molds. Tool steels like S-7 are known for their toughness and ability to withstand high impact. This makes them ideal for applications where durability is critical.

High-Speed Steel

High-speed steel (HSS) is another type of alloy steel that excels in high-temperature environments. HSS maintains its hardness even when exposed to elevated temperatures, making it suitable for cutting tools and molds that require precision. Its ability to retain sharp edges contributes to an excellent surface finish on molded products.

General-Purpose Steels

General-purpose steels are also widely used in mold applications. These steels provide good machining properties and are often more affordable than specialized alloys.

Carbon Steel

Carbon steel is a common choice for molds due to its availability and cost-effectiveness. While it may not offer the same level of corrosion resistance as alloy steels, it can still perform well in less demanding environments.

Stainless Steel

Stainless steel is known for its excellent corrosion resistance, making it suitable for molds exposed to moisture or chemicals. It also provides good dimensional stability, ensuring that your molds maintain their shape over time. AISI P class steels, such as P20, are designed for general-purpose mold applications. They possess good machining properties due to their alloy compositions. The Ni-Cr content improves surface finish and corrosion resistance compared to plain carbon steel. P20 steel is pre-hardened, offering good dimensional stability and can be used directly for mold making. It has excellent machinability and mirror polishing performance, making it a popular choice for many applications.

Mould Steel Requirements

When selecting steel for molds, you must consider several critical requirements. These include high-temperature strength, oxidation resistance, and thermal fatigue performance. Each of these factors plays a vital role in ensuring the longevity and effectiveness of your molds.

High-Temperature Strength

High-temperature strength is essential for molds that operate under extreme conditions. You want steel that maintains its integrity when exposed to heat. The following table outlines some common mold steel grades and their high-temperature strength:

Mold Steel Grade | Tensile Strength (KSI) | Working Temperature (°F) |

|---|---|---|

AISI / SAE H10 | 111.6 | 68 – 842 |

AISI / SAE H13 | 111.6 | 68 – 932 |

AISI / SAE H13 ESR | 111.6 | 68 – 932 |

AISI / SAE S7 | 110.2 | 302 – 752 |

AISI / SAE Toolox 33 | 163.1 | 68 – 1094 |

AISI / SAE Toolox 44 | 205.4 | 68 – 932 |

Choosing a steel grade with high core strength ensures that your molds can withstand the rigors of high-temperature applications without deforming or failing.

Oxidation Resistance

Oxidation resistance is another crucial requirement for mold steel. Molds often face exposure to high temperatures and moisture, which can lead to oxidation and corrosion. Selecting steel with good wear resistance and oxidation resistance helps maintain the mold's performance over time. Stainless steels, such as P-20, are excellent choices for environments where oxidation is a concern. They provide durability and maintain their properties even in challenging conditions.

Thermal Fatigue Performance

Thermal fatigue performance is vital for molds that undergo repeated heating and cooling cycles. As molds experience these temperature fluctuations, they face tensile and pressure-induced stresses. This can lead to surface cracking and reduced dimensional accuracy. According to industry standards, molds should have high resistance to cold and heat fatigue.

Resistance to cold and heat fatigue Some molds are in a state of repeated heating and cooling during the working process, causing the surface of the cavity to be subjected to tensile and pressure-induced stresses, causing surface cracking, spalling, increasing friction, impeding plastic deformation, and reducing dimensional accuracy, thereby resulting in mold failure. Hot and cold fatigue is one of the main forms of hot work die failure. It should have high resistance to cold and heat fatigue.

By focusing on these mold steel requirements, you can ensure that your molds perform effectively and last longer in demanding applications.

Pre-Hardened Options

Pre-hardened steel offers several advantages for mold and die applications. You can use this type of steel directly in production without extensive heat treatment. This feature saves you time and reduces costs. Here are some key benefits of using pre-hardened steel:

Immediate Usability: Pre-hardened steel comes ready for machining and fabrication. You can start working on your molds right away, which speeds up your production process.

Consistent Quality: Manufacturers produce pre-hardened steel with controlled hardness levels. This consistency ensures that you receive reliable material for your projects.

Reduced Risk of Distortion: Since pre-hardened steel undergoes heat treatment before machining, it minimizes the risk of distortion during the machining process. This stability helps maintain the precision of your molds.

Enhanced Machinability: Pre-hardened steels often have good machinability. You can achieve high-quality finishes without excessive wear on your tools.

Versatility: Pre-hardened steel is available in various grades, allowing you to choose the right material for your specific application. Whether you need high wear resistance or good thermal conductivity, you can find a suitable option.

Tip: When selecting pre-hardened steel, consider the specific requirements of your mold application. Look for grades that offer the right balance of hardness and machinability for your needs.

Selection Considerations

When selecting steel for molds and dies, you must consider several important factors. These factors can significantly impact your project's success and efficiency.

Cost Factors

Cost plays a vital role in your decision-making process. You should evaluate the following aspects:

Quality: High-quality steel prevents costly repairs and minimizes downtime during production.

Fast Delivery: Quick delivery times are essential for maintaining production schedules.

Price: Balance the cost with quality and performance. Consider alternatives like pre-hardened steels, which can offer good value.

Different types of steel come with varying costs. For example:

Hardened Tool Steel: Higher upfront costs but lower maintenance costs in the long run.

Standard Tool Steel: Lower initial costs but potentially higher long-term maintenance costs.

Coatings: While coatings can reduce wear, they may increase repair costs if damaged.

Maintenance Requirements

Proper maintenance is crucial for the longevity of your molds. Focus on these key maintenance requirements:

Wear Resistance: Ensure the steel can withstand wear from various sources, including the polymer and ejection system.

Surface Finish: A good surface finish is vital for core and cavity components, affecting product quality.

Dimensional Stability: The material must resist permanent deformation under stress.

Machinability: Choose steel that is easy to machine while ensuring longevity and accuracy.

Corrosion Resistance: This property is important for materials that may release corrosive gases during processing.

Production Volume

Your production volume significantly influences your choice of steel. Consider the following options based on your needs:

P-20H Steel: Ideal for shallow cavity molds and high production volume applications due to its good wear resistance and reasonable price.

H-13 Steel: Designed for high heat applications and deep cavity molds, suitable for high volume production due to its resistance to thermal fatigue and wear.

S7 Steel: Shock-resistant and recommended for die casting molds in high volume production where impact resistance is crucial.

420 Steel: Corrosion-resistant and heat-treatable, often used in medical and food-grade molds, suitable for high-volume production.

4140 Steel: Highly wear-resistant and strong, recommended for heavy-duty applications in high-volume production.

By carefully considering these selection factors, you can choose the best steel for your molds and dies, ensuring optimal performance and durability.

Application Specifics

When selecting steel for molds and dies, consider the specific application. Different industries have unique requirements that influence your choice of material. Here are some key applications and their steel requirements:

Injection Molding:

Use steels with high wear resistance and thermal stability.

H-13 tool steel is a popular choice due to its excellent performance under high temperatures.

Die Casting:

Opt for steels that can withstand high impact and thermal fatigue.

S7 steel is ideal for die casting molds because of its shock resistance.

Blow Molding:

Choose steels that offer good corrosion resistance.

Stainless steels like P20 work well in environments where moisture is present.

Compression Molding:

Select steels that maintain dimensional stability under pressure.

Tool steels with high hardness, such as D2, are suitable for this application.

Thermoforming:

Look for steels with good thermal conductivity.

Aluminum alloys can also be effective due to their lightweight and heat distribution properties.

Tip: Always assess the specific conditions your molds will face. Factors like temperature, pressure, and the type of material being molded can significantly affect your steel choice.

Application | Recommended Steel | Key Properties |

|---|---|---|

Injection Molding | H-13 | High wear resistance, thermal stability |

Die Casting | S7 | Shock resistance, high impact strength |

Blow Molding | P20 | Corrosion resistance |

Compression Molding | D2 | High hardness, dimensional stability |

Thermoforming | Aluminum Alloys | Lightweight, good thermal conductivity |

By understanding the specifics of your application, you can make informed decisions about the best steel for your molds and dies. This approach ensures optimal performance and longevity in your production processes.

Future Trends in Steel Selection

As you look ahead to 2025, several trends will shape your choices in steel for molds and dies. Innovations in steel alloys, sustainability considerations, and advances in manufacturing techniques will play significant roles in your decision-making process.

Innovations in Steel Alloys

Recent advancements in steel alloys have transformed the landscape for molds and dies. You can now find alloys with no or extremely low carbon content. This feature prevents printing cracks in additive manufacturing. Precipitation hardening achieves ultra-high strength, making these steels suitable for demanding applications. Here are some notable alloy options:

Alloy Name | Composition | Hardness (BHN) | Key Features |

|---|---|---|---|

P20+Ni | 285-321 | Most widely used alloy for plastic molding, pre-hardened. | |

Hi-Hard MD® | P20+Ni HH | 321-352 | Enhanced performance, improved wear resistance, and polishability. |

Mold Die®-Xtra | P20 Mod | 285-401 | Increased thermal conductivity and ease of machining. |

420M® | 420 Mod | N/A | Optimized for wear resistance and corrosion resistance. |

DRX® | S7 | N/A | Good wear resistance and toughness, suitable for high-wear applications. |

These innovations enhance wear resistance and durability, ensuring your molds perform effectively over time.

Sustainability Considerations

Sustainability is becoming increasingly important in steel selection. You should consider the environmental impact of your materials. Many manufacturers now focus on producing steels with lower carbon footprints. This shift not only helps the environment but also meets the growing demand for eco-friendly products. By choosing sustainable options, you contribute to a greener future while maintaining high performance in your molds and dies.

Advances in Manufacturing Techniques

Advancements in manufacturing techniques also influence your steel selection. High-speed forging presses improve the steel matrix, reducing chemical segregation and enhancing hardenability. Steel suppliers now provide products squared to tight tolerances, allowing for quick CNC machining. Additionally, pre-hardened steels eliminate the need for heat treating, reducing production time and costs. These improvements streamline your processes and enhance the overall quality of your molds.

By staying informed about these trends, you can make better choices for your molds and dies, ensuring they meet the demands of modern manufacturing.

Choosing the right steel for molds is crucial. It directly impacts the mold's durability, precision, and cost-effectiveness. You must consider factors like hardness, corrosion resistance, and thermal conductivity. These properties ensure optimal performance and longevity.

Key properties include:

Strength and Durability: Essential for mold lifespan and performance.

Corrosion Resistance: Important for maintaining mold integrity over time.

Heat Conductivity: Affects the efficiency of the molding process.

By making informed decisions, you can select the best steels for molds tools and die, leading to better production outcomes and reduced costs.

FAQ

What is the best steel for injection molding?

For injection molding, H-13 tool steel is often the best choice. It offers high wear resistance and excellent thermal stability, making it ideal for high-temperature applications.

How do I determine the right steel for my application?

Consider factors like production volume, temperature conditions, and required properties such as wear resistance and machinability. Assess your specific application needs to make an informed choice.

Are pre-hardened steels worth it?

Yes, pre-hardened steels save time and reduce costs. They come ready for machining, ensuring consistent quality and minimizing distortion during the machining process.

What are the advantages of using stainless steel for molds?

Stainless steel provides excellent corrosion resistance, making it suitable for molds exposed to moisture or chemicals. It also maintains dimensional stability, ensuring molds retain their shape over time.

How can I improve the lifespan of my molds?

To enhance mold lifespan, choose high-quality steel with good wear resistance. Regular maintenance, proper cooling, and avoiding excessive heat can also prolong their durability.