Comparing Vinyl Pressing Plants for Quality Sound

Sound quality is very important for enjoying vinyl records. When you play a record, you want the music to sound deep and complete. The vinyl pressing at szstarlight factory can really change this sound quality. Different plants use different methods and materials that affect the final result. For music lovers, checking out pressing plants like szstarlight factory helps you get high-quality vinyl that meets your needs. If you want the best listening experience, knowing these differences is key.

Key Takeaways

Sound quality is very important for enjoying vinyl records. Pick pressing plants that use good materials and methods.

Vinyl pressing includes mastering, making lacquers, and careful pressing. Each step affects the final sound quality.

Custom options make vinyl records more interesting. Find plants that let you choose colors, sizes, and packaging.

Turnaround times for vinyl pressing can be very different. Plan your releases by talking about timelines with your chosen plant.

Customer reviews give helpful information about pressing plants. Read feedback to check quality and service before deciding.

Overview of Vinyl Pressing

What is Vinyl Pressing?

Vinyl pressing is how we make vinyl records from music. It has many steps, starting with mastering the sound. Mastering makes sure the music sounds good on vinyl. After that, the sound goes onto a lacquer disc. This disc is the master for making the vinyl records.

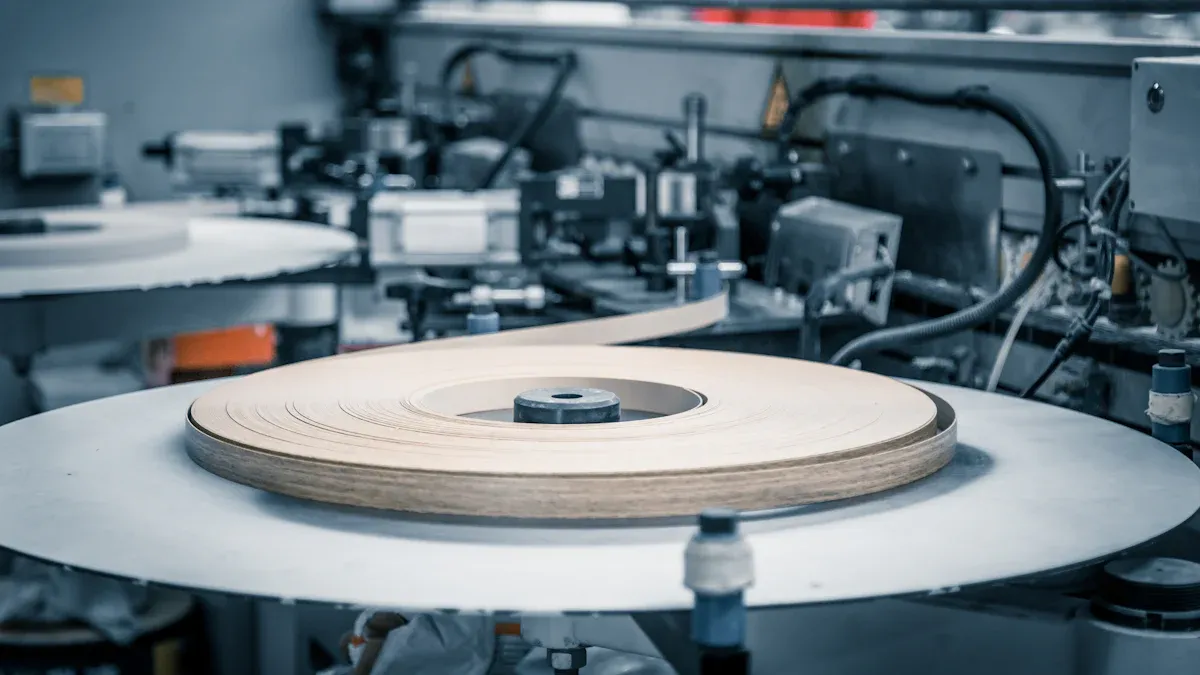

The pressing part heats vinyl pellets until they are soft. Then, the soft vinyl is pressed into a mold to shape it into a record. This method has changed a lot since RCA Victor made the first vinyl long-playing record in 1930. Now, new techniques and tools improve the quality of the final product.

The Importance of Quality in Vinyl Production

Quality is very important in making vinyl records. Good records give a richer and clearer sound. Bad quality can cause distortion and make listening less fun. Things like the materials used and how records are pressed affect the sound quality.

Recently, more people are buying vinyl again. In 2022, vinyl sales were higher than CD sales for the first time since 1987, with 41.3 million sold. This shows that people want quality records. When you look at different pressing plants, remember that not all tapes are mastered well for vinyl. This can change how good the final product is.

Keeping high standards in vinyl pressing is very important. New technology and a focus on being eco-friendly show why quality matters. You want your records to give you the best listening experience possible.

Key Factors in Sound Quality

Materials Used

The materials for vinyl records are very important for sound quality. Most black vinyl records use a mix of polyvinyl chloride (PVC) and carbon black. This mix makes them strong and reduces noise, giving you a better listening experience. On the other hand, colored vinyl records use dyes that can change how the material works. These changes can make the structure uneven, which can hurt sound quality.

The physical traits of vinyl matter too. Flexibility and stiffness are key for sound reproduction. You need a balance that keeps the grooves intact while reducing distortion. Black vinyl usually has this uniformity, but colored vinyl can warp or have surface problems. These issues can cause distortion, so it’s important to think about the materials used in making records.

Pressing Techniques

Pressing techniques greatly affect the quality of vinyl records. Good vinyl pressing needs precise machines that ensure accurate groove cutting. This precision is crucial for making records that sound great. However, colored vinyl might not always get the same care. This can lead to defects that cause skipping or distortion when you play them.

When considering pressing techniques, think about the heat and pressure used during the process. These factors affect how well the vinyl fits the mold. Good pressing techniques create better records that keep the grooves intact. This integrity is important for keeping the sound quality of your favorite songs.

Quality Control Processes

Quality control processes are very important for consistent sound in vinyl production. Pressing plants use different methods to check audio quality and find any noise issues. They focus on things like hit rate, false alarm rate, and how well they can tell the difference. By checking these factors, plants can find problems like clicks that might ruin your listening experience.

For example, a study shows that simpler sound models can find these issues well. This careful approach helps ensure you get high-quality vinyl that meets your needs. When choosing a pressing plant, ask about their quality control processes. Knowing how they keep high standards can help you make a smart choice.

Notable Vinyl Pressing Plants

When you look into vinyl pressing, you will find some great plants. These plants are known for their quality and service. Here are some well-known vinyl pressing companies you should know about.

Gotta Groove Records

Services Offered

Gotta Groove Records has many services for your vinyl pressing needs. They provide:

Custom vinyl pressing

High-quality mastering

Eco-friendly options

Packaging and design services

Notable Projects

This plant has worked with many artists and labels. They have made records that people love. Some notable projects include:

Releases from independent artists

Collaborations with famous labels

Special editions for music festivals

Industry Recognition

Gotta Groove Records is known for being excellent in the industry. They care about quality and customer satisfaction. Their modern equipment and strict quality checks ensure high standards for every record.

Pirates Press

Services Offered

Pirates Press is another top name in vinyl pressing. They offer:

Vinyl pressing in different colors and sizes

Custom packaging solutions

Digital mastering services

Short-run and large-scale production

Notable Projects

Pirates Press has made records for many artists and styles. Some of their notable projects include:

Limited edition releases for popular bands

Collaborations with independent labels

Soundtrack albums for films

Industry Recognition

This plant is well-known for high-quality pressings. Their attention to detail and great customer service make them stand out. Many artists trust Pirates Press for their vinyl needs.

Other Notable Plants

Services Offered

Besides Gotta Groove Records and Pirates Press, there are other great plants for vinyl pressing. These include:

Smashed Plastic: Gained a reputation for high-quality pressings with attention to detail.

Softwax: Famous for excellent vinyl pressing quality and focus on customer satisfaction.

Notable Projects

These plants have made records for many artists, showing their commitment to quality. They have worked on:

Independent artist releases

Special edition vinyl for collectors

Collaborations with major labels

Industry Recognition

Each of these plants is recognized in the industry for their quality and service. They have built strong reputations among audiophiles and artists, making them reliable choices for your vinyl pressing needs.

Comparing Services and Features

Customization Options

When picking a vinyl pressing company, think about their customization options. Many plants let you change your records to match your ideas. You can choose colors, sizes, and special packaging designs. Custom vinyl pressing makes your product more appealing and can make listeners happier.

Research shows that products made with user input usually do better. Here are some benefits of customization:

Interconnectedness: Custom features work together, boosting overall satisfaction.

User-Centric Design: Focusing on ease of use creates fun experiences.

Continuous Innovation: Regular updates keep your product exciting and fresh.

Turnaround Times

Turnaround times are important when you need your records fast. The average time for vinyl pressing has gone up a lot. Now, it can take 10 weeks to five months because of high demand. Some plants even say it could take up to 20 weeks to finish. This delay can hurt independent labels, especially against bigger companies.

Knowing these timelines helps you plan your releases well. If you have a launch date, make sure to talk about it with your chosen plant.

Pricing Structures

Pricing structures differ among vinyl pressing companies. You should compare prices based on the services they provide. Here’s a quick look at how pricing can change:

Category | Year Range | Description |

|---|---|---|

Selling Price Comparison | 2019-2024 | By Regions, Manufacturers, Types, and End Users |

Price, Cost, Revenue Data | 2019-2024 | For different vinyl pressing manufacturers |

In-depth interviews and research show that pricing often reflects service quality. Higher prices might mean better materials and more careful quality checks. Always consider the cost compared to the quality you want from your records.

Customer Reviews and Testimonials

Importance of Feedback

Customer reviews are very important when picking a vinyl pressing plant. They show what other clients experienced. You can find out about the service quality and the final product from these reviews. Feedback helps you see how well a pressing plant keeps its promises. It also points out where they do well or where they need to improve.

Highlighting Positive Experiences

Many customers talk about their good experiences with pressing plants. They often mention great sound quality and careful work on the final record. For example, a customer might say, "The custom vinyl records I got were better than I expected!" These testimonials can help you choose a pressing plant that cares about quality.

Here are some common praises you might see:

Quality of Sound: Customers often highlight the clear and deep music.

Customization Options: Many like being able to create special records just for them.

Timely Service: Fast service usually gets good comments, especially for those in a hurry.

Addressing Common Complaints

While many reviews are good, some customers have concerns. Common complaints include slow service and problems with the final product. For instance, a customer might say, "My record had noise that made it hard to listen." Pressing plants need to address these complaints. They should work to improve their methods and keep customers happy.

When you read reviews, think about both the good and bad feedback. This balanced view will help you make a smart choice when picking a pressing plant for your vinyl records.

Picking the right pressing plant is very important for great vinyl records. You want your music to sound amazing. Think about important things like materials, pressing methods, and quality checks.

Choosing a good pressing plant makes sure high-quality digital sources are used. This helps improve your listening experience and explains why premium records cost more.

When you make a smart choice, you can enjoy the rich sound that only good vinyl gives. Happy listening! 🎶

FAQ

What should I look for in a vinyl pressing plant?

Look for materials, pressing methods, and quality checks. These things really affect sound quality. Also, check if they offer customization and how long it takes to get your records.

How long does vinyl pressing usually take?

Vinyl pressing can take 10 weeks to five months. This depends on how busy the plant is. Always ask about the timeline to plan your release well.

Are colored vinyl records of lower quality?

Colored vinyl might have lower sound quality sometimes. This is because the material can be uneven. Black vinyl usually has better sound and consistency. Still, many plants make high-quality colored records too.

Can I customize my vinyl records?

Yes! Most pressing plants let you customize your records. You can pick colors, sizes, and packaging designs to make a unique product that shows your style.

How important are customer reviews when choosing a pressing plant?

Customer reviews are very helpful when picking a pressing plant. They give you insights into the plant's quality and service. Reviews help you understand others' experiences and spot any problems, so you can make a smart choice.