The Science Behind Nitrogen Generators Explained

Nitrogen generation systems produce nitrogen gas using advanced technology. These systems extract nitrogen from the air, providing a consistent supply of pure nitrogen. More industries are adopting nitrogen generation systems nowadays, making it essential to understand their operation. This knowledge will assist you in selecting the best system for your needs. For instance, the nitrogen generation system market is projected to grow by 4.8% annually from 2023 to 2032, indicating a robust demand for nitrogen gas.

Key Takeaways

Nitrogen generators make pure nitrogen gas from the air. This gas is important for industries like food, medicine, and electronics.

Making nitrogen on-site can save businesses up to 80% compared to old supply methods. This makes it a smart money choice.

Knowing the differences between PSA and membrane technologies helps you pick the best nitrogen generator for your needs.

Taking care of nitrogen generators keeps them working well and lasting longer. This stops sudden breakdowns and expensive repairs.

Using on-site nitrogen generation lowers carbon emissions. It also helps make industrial processes more eco-friendly.

What Are Nitrogen Generators?

Nitrogen generators are machines that make nitrogen gas from the air. They are very important in many industries. They provide a steady supply of pure nitrogen. This gas is needed for many uses, like keeping food fresh, making electronics, and producing medicines.

Definition and Purpose

A nitrogen generator works by taking nitrogen out of other gases in the air, mostly oxygen. The main technologies used are pressure swing adsorption (PSA) and membrane separation. These methods help you get nitrogen gas that is 99.999% pure. This high purity is very important in industries like electronics. Even a tiny bit of oxygen can harm sensitive parts.

Applications of Nitrogen Generators

Nitrogen generators are used in many different fields. Here are some key areas where they are very helpful:

Industry Sector | Application Description |

|---|---|

Chemical and Petrochemical | High-purity nitrogen keeps chemical reactions safe by using inerting, blanketing, and purging. |

Food and Beverage | Nitrogen replaces oxygen in packaging, which helps food last longer and stay fresh. |

Pharmaceutical | It keeps safe environments during production to stop oxidation and contamination of sensitive products. |

Electronics | Nitrogen creates clean spaces for making semiconductors and testing parts, ensuring products work well. |

Using nitrogen gas can improve the quality and safety of your products. For example, in the food industry, nitrogen helps keep food fresh by stopping spoilage. In electronics, it protects delicate parts during making. Nitrogen generators are very important in today’s industrial processes.

How Do Nitrogen Generators Work?

Nitrogen generators work in clear steps to get nitrogen gas from the air. Knowing this process helps you see how these systems make pure nitrogen quickly.

Overview of the Process

The nitrogen generation process has several important steps:

Step | Description |

|---|---|

Air Compression | Air from the environment is compressed to 0.6 – 0.8 MPa to help clean and cool it. |

Air Purification | A pre-cooling system and molecular sieve remove impurities. This keeps the dew point below -65°C and carbon dioxide below 1×10⁻⁶. |

Air Liquefaction | Clean air is cooled to -196°C and turned into liquid using a throttle valve. |

Distillation Separation | Liquid air is distilled to separate nitrogen and oxygen by their boiling points, making high-purity nitrogen (up to 99.999%). |

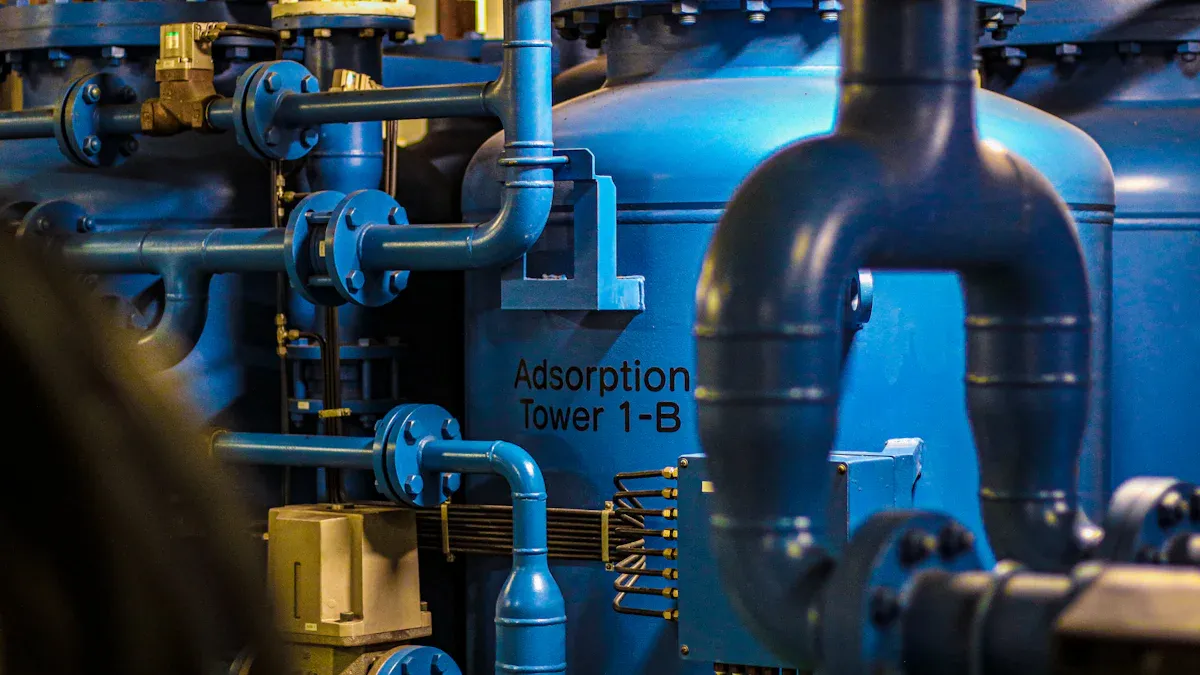

PSA Technology Explained

Pressure swing adsorption (PSA) is a common method in nitrogen generators. This technology uses carbon molecular sieve (CMS) to separate nitrogen from compressed air. Here’s how it works:

Compressed air goes into two towers filled with CMS.

Oxygen sticks to the sieve, letting nitrogen pass through.

The system switches between towers to keep nitrogen flowing.

PSA technology makes very pure nitrogen, which is good for many uses. Studies show it can create nitrogen with very low oxygen levels, as low as 10 ppm.

Membrane Technology Explained

Membrane nitrogen generators use special membranes to separate gases. This method increases nitrogen while getting rid of other gases. Here’s a quick look at how it works:

Compressed air moves through hollow fiber membranes.

Nitrogen goes through the membranes, while oxygen and other gases are left behind.

This technology starts up quickly, usually in about three minutes.

Membrane nitrogen generators are small and easy to set up. They give a steady supply of nitrogen, but may need extra technology for purities over 99%.

Comparing PSA and Membrane Technologies

When picking between PSA and membrane technologies for nitrogen generators, think about a few things. These include how well they work, their cost, and how much care they need.

Efficiency and Output

PSA and membrane nitrogen generators work differently. Here’s a quick look at how they compare:

Feature | PSA Nitrogen Generators | Membrane Nitrogen Generators |

|---|---|---|

Up to 99.999% | Up to 99.95% | |

Startup Time | 15 – 30 minutes | N/A |

Footprint | N/A | 40-60% less than PSA |

Maintenance Cost | Higher | Lower due to fewer moving parts |

Air Consumption | Similar or slightly lower | Similar or slightly lower |

PSA systems let you change nitrogen purity from 95% to 99.999%. Membrane systems give steady output but may not be as pure. Membrane nitrogen generators are lighter, which can save space for more cargo or fuel.

Cost Considerations

Cost is very important in your choice. Making nitrogen on-site can save you almost 80% compared to renting. A small-flow nitrogen generator costs between $3,000 and $20,000. High-flow generators can cost over $100,000. A cylinder of nitrogen gas is about $350. LabSource's study shows that on-site nitrogen generation pays off quickly, showing big savings.

Maintenance and Operation

Taking care of the system is key for it to work well. Keeping a log of maintenance helps you track checks and repairs. This way, you can spot patterns and predict problems. Regular care follows the manufacturer’s advice and makes the system more reliable. Good maintenance stops unexpected breakdowns, keeping everything running smoothly. Checking parts like air filters and valves often helps find problems early, making the equipment last longer.

Benefits of On-Site Nitrogen Generation

Cost Savings

Making nitrogen on-site can save you a lot of money. When you produce nitrogen gas yourself, you don’t need to buy or move nitrogen cylinders. This can save you up to 80% compared to regular ways of getting nitrogen. You also skip the costs of renting and delivering cylinders. Buying a nitrogen generation system can pay off fast, especially for businesses that need a lot of nitrogen.

Reliability and Consistency

On-site nitrogen generation gives you a steady supply of high-quality nitrogen. You won’t have to depend on outside suppliers, which can cause delays or shortages. Having your own nitrogen generators means you get the gas when you need it. This is very important for industries like pharmaceuticals and electronics, where good nitrogen quality matters. With specially designed nitrogen systems, you can adjust the output to fit your needs, keeping your operations running well.

Environmental Impact

On-site nitrogen generation is also good for the environment. By not needing transportation, you cut down on carbon emissions from traditional nitrogen supply methods. This method uses less energy and produces fewer greenhouse gases than regular nitrogen sourcing. Plus, using air as a raw material avoids the energy-heavy extraction and cleaning processes, which helps reduce the use of fossil fuels.

By choosing on-site nitrogen generation, you improve your efficiency and help create a more sustainable future.

Nitrogen generation systems are very important in many industries. They give a steady supply of high-quality nitrogen, which is needed for many uses. If you know how these systems work, you can choose what fits your needs best.

Think about the good things that on-site solutions offer. They can really boost efficiency and lower costs. For example, LabSource used a Peak i-Flow generator. This helped them have a steady nitrogen supply and lower costs. On-site generation can bring costs down to $0.15 - $0.30 CCF, saving 88% or more. 🌱

Buying nitrogen generation systems can help make your work better and more eco-friendly.

FAQ

What is the main advantage of using nitrogen generators?

Nitrogen generators give you a steady supply of pure nitrogen right where you need it. This means you don’t have to rely on outside suppliers. It also helps save money and keeps the quality consistent for many uses.

How long does it take to install a nitrogen generator?

The time to install a nitrogen generator depends on its size and how complex it is. Usually, it takes about one to three days to set up, based on what you need.

Can nitrogen generators operate in all environments?

Yes, nitrogen generators can work in many different places. But very hot or humid conditions might affect how well they work. Make sure to pick a system that fits your specific environment.

What maintenance do nitrogen generators require?

You need to check filters, valves, and pressure gauges regularly. It’s also important to look for leaks and do routine checks to keep everything running well and lasting longer.

Are nitrogen generators energy-efficient?

Yes, nitrogen generators use energy wisely. They make nitrogen from compressed air, which uses less energy than traditional methods. This can help you save a lot of money over time.