How to Select the Best Disposable Mask Making Machine

Choosing the right disposable 2D mask blank machine factory is very important for producing high-quality masks. The worldwide market for these machines is expected to be about USD 2.5 billion by 2032, indicating a growing need for them.

When selecting a machine from a disposable 2D mask blank machine factory, consider important factors such as the production capacity, the types of materials it can handle, and its operational speed. These elements will significantly impact your ability to manufacture quality masks. Taking the time to make an informed decision will ensure you invest in a machine that meets your specific requirements.

Key Takeaways

Think about what kind of machine you want: fully automatic, semi-automatic, or manual. Each type is good for different needs and budgets.

Look at how many masks the machine can make and what materials it can use. Pick machines that fit your needs.

Check the manufacturer's reputation and support after you buy. A good manufacturer gives helpful support and new technology.

Know your budget. Consider both the starting costs and future expenses, like maintenance and supplies.

Look into financing options. Find services that can help you pay for mask making machines.

Types of Mask Making Machines

When you choose a mask making machine, there are three main types: fully automatic, semi-automatic, and manual machines. Each type has special features and benefits for different production needs.

Fully Automatic Machines

Fully automatic machines are the most common. They are very efficient and can produce many masks quickly. These machines can make different kinds of medical masks, like N95 and surgical masks, all at once. They work on their own, doing tasks like cutting, attaching ear bands, and delivering masks without help.

Here are some key benefits of fully automatic machines:

They can make many masks in less time.

They are efficient and accurate in making masks.

They have easy-to-use touch screens for control.

Semi-Automatic Machines

Semi-automatic machines balance cost and efficiency. They are good for small to medium businesses that want to boost production. These machines need several workers to run but can make up to 120 masks each minute.

Machine Type | Workers Needed | Capacity (pcs/min) | Stability |

|---|---|---|---|

Fully Automatic | 2 | 80-90 | Hard to fix |

Semi-Automatic | Several | Up to 120 | Easier to fix |

Many businesses like semi-automatic machines because they are flexible and cost less than fully automatic ones.

Manual Machines

Manual machines are useful for small operations, especially where money is tight. They are popular for their flexibility and low cost, making them great for making special masks in small businesses.

Even though the manual market is the smallest, it is still important in places with less industry. These machines serve niche markets where demand is low, making them a good choice for small companies. While they are not as fast as automatic machines, manual mask making machines are important for being affordable and easy to use.

Key Specifications to Consider

When you pick a disposable mask making machine, think about some key features. These features will help you find the best machine for your needs.

Production Capacity

The production capacity of mask making machines can be very different. Automatic machines can make about 35 to 50 masks every minute. This faster speed helps you produce more masks. If you need to make a lot of masks, choose machines with higher production capacity.

Here’s a quick look at typical production capacities:

Machine Type | Capacity (pcs/min) |

|---|---|

Fully Automatic | 35-50 |

Semi-Automatic | Up to 120 |

Manual | Varies, usually lower |

Material Compatibility

Material compatibility is very important for making good masks. Different machines can use different filter materials. Make sure the machine you choose can work with the materials you want to use.

Check these important tests for material compatibility:

Test Type | Description |

|---|---|

Bacterial Filtration Efficiency | Shows how well materials stop bacteria. |

Particle Filtration Efficiency | Checks how well materials filter out airborne particles. |

Fluid Resistance | Tests how well the material stops fluids from getting through. |

Differential Pressure | Measures how easy it is to breathe through the mask material. |

Machine Dimensions

The size of the mask making machine is important, especially if you have little space. Make sure the machine fits well in your area. Also, think about how heavy the machine is. Heavier machines might need stronger floors and support.

Speed and Efficiency

Speed and efficiency are very important when choosing a mask making machine. You need a machine that makes masks fast while keeping quality high. Different machines work at different speeds, which can change how much you can produce.

Semi-automatic machines make masks quickly, balancing cost and efficiency. They usually produce 50 to 120 masks each minute, depending on the type. This speed helps you meet demand without overworking your team.

Fully automatic medical mask making machines are even more efficient. They can create a lot of masks fast, improving overall production. These machines lower labor costs and increase output, making them great for bigger businesses.

When thinking about speed, consider how it affects your work process. Faster machines help you meet market needs better. If you own a small or medium business, getting a semi-automatic machine could be a smart idea. This type is expected to grow as more small and medium manufacturers appear.

Factors Influencing Your Choice

When you choose a disposable mask making machine, many factors can affect your choice. Knowing these factors helps you decide better.

Manufacturer Reputation

The reputation of the machine makers is very important. A well-known maker usually means they are reliable and make good products. Look for companies that are known for their new technology. This includes things like touch screens and energy-saving parts. Also, see how they respond to what customers want. A good manufacturer creates new models to meet different needs in making face masks.

Factor | Description |

|---|---|

Technological Advancements | Ongoing improvements in design and how the machine works. |

Market Demand | Makers create new models to fit different customer needs. |

Application Needs | Machines are designed for specific tasks in making face masks. |

Regulatory Influences | Government rules set quality standards and offer financial help for buying machines. |

After-Sales Service

After-sales service is another key factor. You want to make sure the maker gives good support after you buy. Good after-sales service includes one year of free help for problems not caused by people and lifetime technical support. This support means you get quick help when issues come up. Choosing makers with strong backgrounds can help you solve problems faster.

Service Type | Description |

|---|---|

After-sale service | One year of free service (not for human errors) with lifetime technical help. |

Perfect after-sales service | Pick makers who provide great after-sales service for quick fixes. |

Warranty Options

Warranty options are also important when picking a mask making machine. A good warranty protects your investment. Look for machines that have at least a 12-month warranty, which usually includes online help and local support. This warranty ensures you can get help when you need it.

Warranty Duration | Support Type |

|---|---|

12 months | Online technical support |

Local agent assistance |

By thinking about these factors, you can make a smarter choice when buying a disposable mask making machine.

Budget Considerations

When you think about buying mask making machines, your budget is very important. You need to look at both the starting cost and the ongoing costs of running the machine.

Initial Investment vs. Long-Term Costs

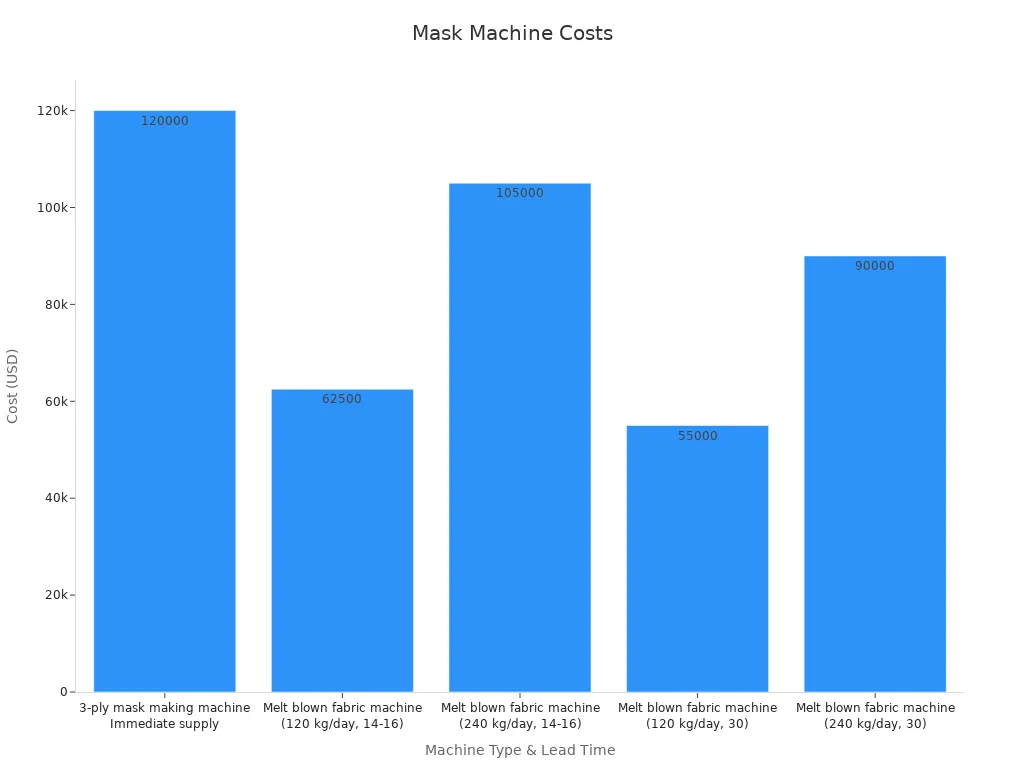

The starting cost for mask making machines can change a lot based on the type and features. For example, a 3-ply mask making machine costs about $120,000. On the other hand, melt blown fabric machines cost between $55,000 and $105,000, depending on how much they can produce. Here’s a list of some common costs:

Item Description | Cost (USD) | Lead Time (Days) |

|---|---|---|

3-ply mask making machine | $120,000 | Immediate supply |

Melt blown fabric machine (120 kg/day) | $62,500 (14-16) | 14-16 |

Melt blown fabric machine (240 kg/day) | $105,000 (14-16) | 14-16 |

Melt blown fabric machine (120 kg/day) | $55,000 (30) | 30 |

Melt blown fabric machine (240 kg/day) | $90,000 (30) | 30 |

While the starting cost is important, you also need to think about long-term costs. These include maintenance, energy use, and labor costs. A machine that looks cheaper at first might cost more later if it needs many repairs or uses a lot of energy.

Cost of Consumables

Consumables are another big expense. These are raw materials like non-woven fabric, filters, and ear loops. The prices of these materials can change based on market demand. You should figure out the cost of consumables to better understand your total budget.

Financing Options

Financing options can help you handle the costs of buying mask making machines. Here are some common ways:

Escrow services: These services make sure payments are safe for big purchases, lowering risks.

Distributors: They offer support and help you enter markets without needing a direct manufacturer.

Direct sales: This option lets large buyers customize solutions and build strong ties with suppliers.

By thinking about these budget factors, you can make a smarter choice when buying mask making machines.

Choosing the best disposable mask making machine needs careful thought. You should look at the type of machine, how many masks it can make, and what materials it can use. Knowing what you need is very important.

Here are some key points to keep in mind:

Strengths: High need for face masks and easy access to materials.

Weaknesses: High starting costs and limited tech skills.

Opportunities: Increasing online sales and new technology.

By doing good research and checking your choices, you can make a smart decision that fits your business goals.

Category | Details |

|---|---|

Machine Type | Automatic, Semi-Automatic, Manual |

Application | Medical Masks, Surgical Masks, N95 Respirators |

End-User | Hospitals, Clinics, Manufacturing Units |

Sales Channel | Direct Sales, Distributors, Online Sales |

Investing in the right machine can help you make masks successfully and meet the growing market need.

FAQ

What is the average cost of a disposable mask making machine?

The price can be very different based on the machine type. Fully automatic machines usually cost around $120,000. Semi-automatic machines often range from $55,000 to $105,000.

How long does it take to set up a mask making machine?

The setup time depends on the machine type and how complex it is. Usually, it takes about 1 to 3 days to install and test before you can start making masks.

What materials do I need for mask production?

You will need non-woven fabric, filters, and ear loops. Make sure your machine can work with these materials for the best results.

How often should I maintain my mask making machine?

Regular maintenance is very important. Plan to maintain the machine every 3 to 6 months to keep it running well and avoid problems.

Can I produce different types of masks with one machine?

Yes, many machines can make different types of masks. But, check the details to make sure they can handle various designs and materials.