Understanding How Nitrogen Generator Systems Operate

Nitrogen generator systems are important for making nitrogen gas. They use two main methods: PSA (Pressure Swing Adsorption) and Membrane. Each method has its own advantages and uses. Knowing how these methods work helps you pick the best nitrogen generator for you. For example, in the food and drink industry, nitrogen generator systems keep products fresh by removing oxygen. This helps products last longer.

Key Takeaways

Nitrogen generator systems make nitrogen gas where you need it. This saves money and works better.

There are two main types: PSA and Membrane. PSA gives high purity, while Membrane needs less care.

Regular maintenance is very important for best performance. Plan routine checks and keep the system clean.

Nitrogen is important in many industries. These include food packaging, electronics, and medicine. It helps improve product quality and safety.

Picking the right nitrogen generator depends on your needs. Think about purity, flow rate, and space.

Overview of Nitrogen Generation Systems

Nitrogen generation systems are very important for making nitrogen gas. They help you create nitrogen right where you need it. This can save money and make things work better. You can pick from two main types: PSA (Pressure Swing Adsorption) and Membrane. Each type has special features for different needs.

Key Components of Nitrogen Generation Systems

Air Compressor: This part squeezes air from the environment. Air is about 78% nitrogen.

Separation Unit: This part takes out nitrogen from other gases like oxygen and carbon dioxide.

Storage Tank: After separation, nitrogen gas goes into a tank for later use.

Benefits of On-Site Nitrogen Generation

Using a nitrogen generator has many benefits:

Cost Savings: You can save money by making nitrogen gas yourself instead of buying it.

Continuous Supply: You get a steady supply of nitrogen gas, which is important for processes needing constant nitrogen.

Customization: Special nitrogen generation systems let you adjust the output to fit your needs for purity and flow rate.

By learning how nitrogen generation systems work, you can choose the best one for you. Whether you need nitrogen for food packaging, electronics, or medicine, knowing the process helps you improve your work.

PSA Technology in Nitrogen Generators

How PSA Works

Pressure Swing Adsorption (PSA) technology is key for nitrogen generation systems. This method separates nitrogen from other gases in the air, mainly oxygen and argon. Here’s how it works:

Air Compression: The system uses an air compressor to squeeze air from the environment.

Adsorption: The compressed air goes through a separation unit filled with special materials. These materials trap oxygen and other gases while letting nitrogen pass through.

Pressure Release: After some time, the pressure drops in the system. This drop allows the materials to release the trapped gases, preparing them for the next cycle.

Nitrogen Collection: The pure nitrogen gas is then gathered and stored in a tank for later use.

This process keeps repeating, giving a steady supply of high-quality nitrogen gas.

Advantages of PSA Systems

PSA systems have many benefits that make them a great choice for on-site nitrogen generation:

High Purity Nitrogen: PSA technology can create nitrogen that is up to 99.999% pure. This high purity is important for many uses, like food packaging and making electronics.

Cost-Effective: By making nitrogen on-site, you can save money compared to buying bottled nitrogen. This helps lower costs over time.

Reliability: PSA systems are known for being reliable. They provide a steady supply of nitrogen, which is important for processes that need constant nitrogen.

Efficiency: The efficiency of PSA technology can be shown through key performance indicators. For example, product purity shows how much nitrogen is in the output. Also, productivity measures how much nitrogen is made over time, ensuring you get the most from your system.

Here’s a quick overview of some performance metrics for PSA systems:

Performance Indicator | Description |

|---|---|

Product Purity | The amount of nitrogen in the product stream, including argon. |

Productivity | The amount of nitrogen produced over time, based on flow meter readings. |

Air Demand | The amount of air needed for the nitrogen generation process, calculated from flow meter data. |

By knowing how PSA technology works and its benefits, you can make smart choices about your nitrogen generation needs.

Membrane Technology in Nitrogen Generators

How Membrane Systems Operate

Membrane technology is another good way to make nitrogen. This method uses special filters to separate nitrogen from other gases in the air. Here’s how it works:

Air Intake: The system pulls in air from the surroundings. This air has about 78% nitrogen.

Membrane Separation: The air goes through a filter that lets nitrogen pass while blocking oxygen and other gases. This creates a stream of very pure nitrogen.

Collection: The separated nitrogen gas gathers in a storage tank for immediate use or later.

Membrane systems run all the time, giving a steady supply of nitrogen. They can adjust to different needs, making them useful for many tasks.

Benefits of Membrane Technology

Membrane nitrogen generators have many benefits that make them great for on-site nitrogen production:

High Purity Levels: Many membrane systems can reach nitrogen purity levels up to 99.9995%. This pure nitrogen is important for industries like electronics and medicine.

Low Maintenance: Membrane systems need very little upkeep. For example, the Infinity 1032 can run for 24 hours with little care.

Versatility: Membrane systems can work with different flow rates. The i-FlowLab 6XX2 can manage flow rates from 21 to 1236 L/min, meeting various needs.

Efficiency: Bigger membrane areas improve nitrogen separation. The right pressure helps performance, while controlled feed rates stop efficiency losses.

Here’s a quick overview of some models and their performance:

Model | Flow Rate (L/min) | Purity (%) |

|---|---|---|

Infinity 1032 | Up to 38 | Not specified |

i-FlowLab 6XX2 | 21-1236 | Up to 99.9995 |

Solaris XE | Up to 35 | Up to 99.5 |

Infinity XE 503X | 30-390 | 95-99.5 |

By knowing how membrane systems work and their benefits, you can make smart choices about your nitrogen generation needs.

Comparing PSA and Membrane Technologies

Efficiency and Purity of Nitrogen Generation

When you look at PSA and membrane technologies, efficiency and purity are very important. PSA systems can make nitrogen that is up to 99.9995% pure. This high purity is great for industries that need strict quality. On the other hand, membrane systems usually reach purity levels between 95% and 99.9%. This is good enough for many low-flow uses, like food packaging, but may not work for tougher processes.

Here’s a quick comparison of the two technologies:

Technology Type | Purity Level | Application | Operational Characteristics |

|---|---|---|---|

Membrane | 95% - 99.9% | Low-flow applications (e.g., food packaging) | Small, low maintenance, fits in tight spaces |

PSA | High purity | Industrial applications needing high purity | Efficient, cost-effective, uses pressure swing adsorption process |

Cost Considerations for Nitrogen Generator Systems

Cost is a big part of your decision. Making nitrogen on-site with PSA can save money and help the environment compared to older methods like fractional distillation. For example, running a PSA nitrogen generator costs about $0.15 for every hundred cubic feet (CCF). In contrast, liquid nitrogen can cost up to $1 per CCF, especially in remote places where it is hard to find.

Also, transportation costs can add to the total price of nitrogen from fractional distillation. This is especially true in places like Puerto Rico, where local supply is low. By choosing an on-site nitrogen generator, you can avoid these extra costs and have a steady supply of nitrogen.

Installation Considerations for Nitrogen Generation Systems

When you plan to install a nitrogen generation system, think about space and upkeep. Good planning helps your system work well and meet your needs.

Space Requirements for Nitrogen Generators

The space needed for nitrogen generators depends on the type and size. Here are some important points to think about:

Purity Level: Different jobs need different purity levels. For example, labs often need very pure nitrogen (99.9995%), while breweries may only need 99.5% purity.

Flow Rate: Figure out how much nitrogen you use and how long you run it. This helps you know what size system you need.

Pressure Requirements: Some nitrogen generators can give up to 130 psi, but high-pressure jobs may need around 400 psi.

Compressor Demand: Check how much your current compressor can handle. You might need to upgrade it to work well with the nitrogen generator.

To help you see the space needed, here’s a table showing different types of nitrogen generators and their sizes:

Type | Capacity (Sprinkler Volume) | Dimensions (H x W x D) | Floor Space Required |

|---|---|---|---|

Wall-Mounted | Up to 2,000 gallons | 36.5” x 24.5” x 9.25” | None |

Skid-Mounted | Up to 3,200 gallons | 57” x 32” x 40” | Yes |

Stand-Alone | Up to 22,500 gallons | N/A | 2 square feet |

Maintenance Needs of Nitrogen Generation Systems

Regular upkeep is very important for your nitrogen generation system to last and work well. Here are some maintenance tips:

Routine Checks: Plan regular inspections to make sure everything works right. This includes checking filters, compressors, and storage tanks.

Cleaning: Keep the system clean to avoid contamination. Dust and dirt can lower nitrogen purity.

Monitoring Performance: Watch performance measures like nitrogen purity and flow rate. This helps you spot problems early.

Professional Servicing: Think about hiring experts for tricky maintenance tasks. They can help and make sure your system runs well.

By knowing these installation points, you can get the most out of your on-site nitrogen generation system.

Applications of Nitrogen Generator Systems

Food Packaging with Nitrogen Generators

Nitrogen generator systems are very important for food packaging. They help keep food fresh by stopping oxidation. You often see nitrogen used in Modified Atmosphere Packaging (MAP). This method replaces oxygen in packages with nitrogen, which helps food last longer. For example, nitrogen keeps snacks fresh and stops spoilage in foods that go bad quickly. The need for nitrogen in food packaging is high because it makes sure products stay safe and tasty during shipping.

Electronics Manufacturing Using Nitrogen Generation Systems

In electronics manufacturing, nitrogen is very important for many tasks. You can save money by making nitrogen on-site, which can cut costs by up to 80% compared to buying in bulk. Having nitrogen available all the time lets your work run 24/7 without breaks. This is key for keeping production on schedule. Also, nitrogen makes things safer by lowering risks from handling high-pressure tanks. You can change nitrogen purity levels to fit specific needs, ensuring the best results in making semiconductors and flat-panel displays.

Pharmaceutical Industry Applications of Nitrogen Generators

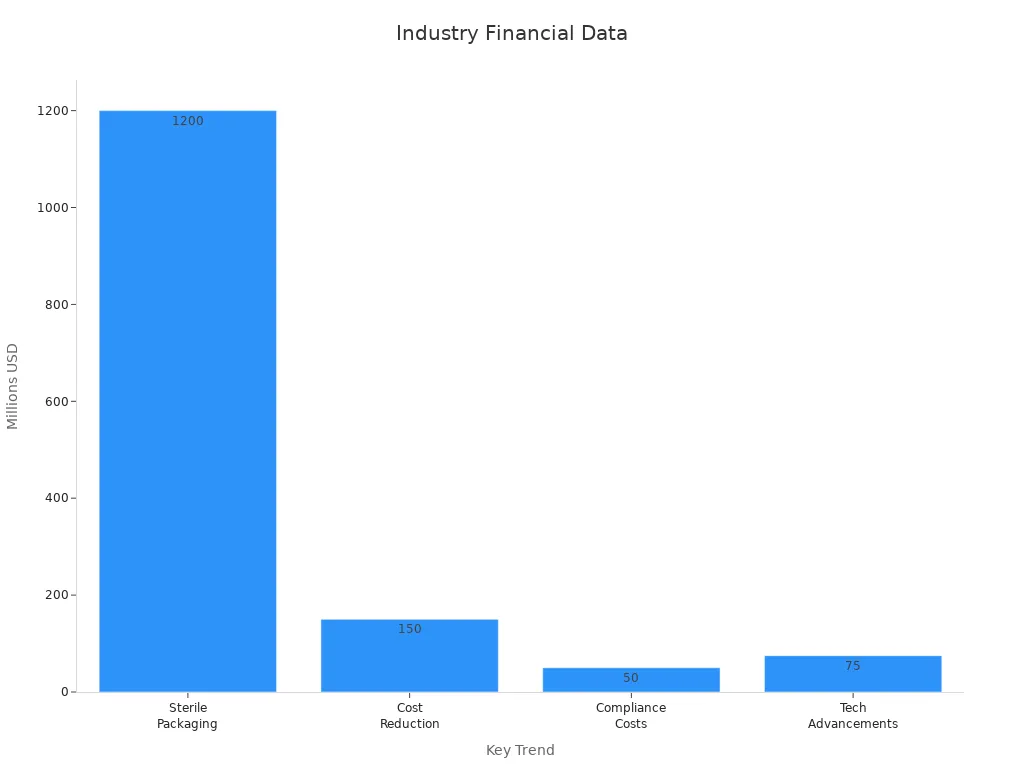

Nitrogen generator systems are becoming more important in the pharmaceutical industry. They help create clean spaces for making and packaging drugs. The need for sterile packaging is expected to reach about $1.2 billion by 2023, growing at 8% each year. Using nitrogen in production can save a lot of money, around $150 million each year. This efficiency helps companies follow strict rules while keeping costs low.

By learning about these uses, you can see how nitrogen generator systems help different industries. They improve product quality, lower costs, and make things safer in many areas.

Nitrogen generator systems are very important in many industries. They supply nitrogen for things like food packaging and making electronics. Knowing the differences between PSA and membrane technologies helps you choose wisely. Each type has its own benefits, making work easier and cheaper.

Good installation and care are key for your nitrogen generator to work well and last long. By using these systems, you support eco-friendly goals while meeting the rising need for nitrogen.

The nitrogen generator market is growing because of industry needs.

New technology boosts efficiency, saving up to 30% energy.

The global semiconductor market will hit $1 trillion by 2030, raising nitrogen demand.

Take advantage of nitrogen generator systems to improve your work.

FAQ

What is a nitrogen generator?

A nitrogen generator makes nitrogen gas from the air. It uses methods like PSA or membrane separation to get nitrogen. This gives a steady supply for different uses.

How does a nitrogen generator save costs?

Using a nitrogen generator saves money by making nitrogen on-site. This means you don’t have to buy bottled nitrogen, which cuts down on transport costs.

What industries benefit from nitrogen generators?

Many industries use nitrogen generators. These include food packaging, electronics, and pharmaceuticals. These systems help keep products safe and high quality.

How often should I maintain my nitrogen generator?

You should check your nitrogen generator every few months. This includes looking at filters, compressors, and storage tanks to keep everything working well.

Can I customize the purity level of nitrogen produced?

Yes, you can change the purity level of nitrogen from your generator. Different uses need different purity levels, and systems can be adjusted to fit.