Understanding Nitrogen Generators and Their Key Applications

Nitrogen generators LLC produces nitrogen gas on-site, eliminating the need for bulky storage tanks or cylinders. These systems offer a continuous supply of nitrogen, making them cost-effective and eco-friendly. Industries utilize nitrogen generators for various applications, including:

Food and Beverage: Extending shelf life through packaging.

Pharmaceuticals: Maintaining medication integrity.

Aerospace: Enhancing safety in fuel tanks.

Oil and Gas: Supporting oil recovery and pipeline safety.

By using nitrogen generation systems from nitrogen generators LLC, businesses can streamline operations and reduce costs.

Key Takeaways

Nitrogen generators make nitrogen gas right where it's needed. This cuts down on storage tanks and saves money.

Industries such as food and drinks use nitrogen to keep products fresh and safe with special packaging.

In medicine, nitrogen generators help keep drugs safe and ensure quality by giving high-purity nitrogen.

The aerospace industry uses nitrogen generators to keep fuel tanks safe and stop rust during testing.

Picking the right nitrogen generator means looking at purity needs, flow rates, and what you need it for.

How Nitrogen Generators Work

Overview of Nitrogen Generation Process

Nitrogen generators operate through a series of well-defined steps. Understanding these steps helps you appreciate how these systems produce nitrogen efficiently. Here’s a simplified breakdown of the nitrogen generation process:

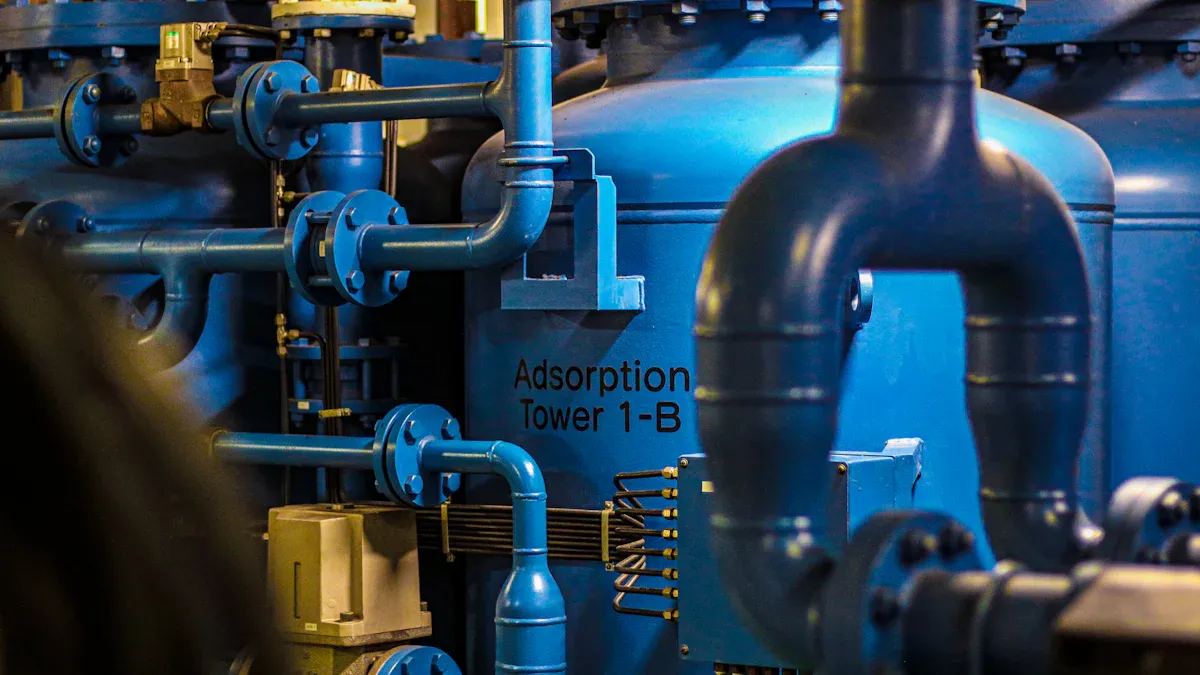

Adsorption Stage: Compressed air enters the nitrogen generator. During this stage, oxygen, water vapor, and carbon dioxide molecules diffuse into the adsorbent's pore structure. Meanwhile, nitrogen molecules pass through the adsorber.

Regeneration Stage: The system releases the adsorbed components back into the atmosphere. This step prepares the adsorbent for the next cycle.

Pressure Regulation: The generator alternates between two adsorber vessels. One vessel produces nitrogen at above-atmospheric pressure, while the other regenerates at below-atmospheric pressure.

This process ensures a continuous supply of nitrogen for various applications.

Types of Nitrogen Generators

You can find several types of nitrogen generators, each designed for specific needs. Here are the most common types:

PSA (Pressure Swing Adsorption)

The PSA nitrogen generator uses two adsorption towers filled with adsorbent materials. Compressed air flows into one tower, where it separates nitrogen from other gases. The system then switches to the second tower, allowing the first to regenerate. This method can achieve purity levels of up to 99.999%, making it suitable for high-demand applications.

Membrane Technology

Membrane nitrogen generators utilize hollow polymer fibers to separate nitrogen from air. The selective permeability of these fibers allows nitrogen to pass through while blocking other gases. This type of generator is energy-efficient and requires low maintenance. It typically produces nitrogen with purity levels ranging from 95% to 99.5%.

Type of Generator | Purity Levels | Flow Rates | Energy Efficiency | Maintenance Requirements |

|---|---|---|---|---|

Membrane | 95% to 99.5% | Up to 15,000 cubic feet per hour | Most energy-efficient | Low maintenance |

PSA | Up to 99.999% | Up to 130,000+ cubic feet per hour | Moderate energy requirements | Routine maintenance needed |

By understanding these types, you can choose the right nitrogen generator for your specific needs.

Applications of Nitrogen Generators

Nitrogen generators play a crucial role across various industries. Their applications enhance safety, quality, and efficiency. Here’s how they impact different sectors:

Food and Beverage Industry

Packaging and Preservation

In the food and beverage industry, nitrogen generators significantly improve packaging processes. By replacing oxygen with nitrogen, you inhibit the growth of bacteria and mold. This action reduces spoilage and helps maintain freshness. Here are some key benefits:

Nitrogen prevents oxidation, preserving the visual appeal, flavor, and nutritional value of food.

Modified atmosphere packaging (MAP) creates nitrogen-rich environments that enhance food safety and sensory attributes.

Nitrogen flushing extends shelf life by months, preventing undesirable changes due to oxygen exposure.

Inerting Processes

Nitrogen generators also support inerting processes. They create an inert atmosphere during food processing, which minimizes the risk of contamination. This application is vital for maintaining the quality of perishable goods.

Pharmaceutical Industry

Drug Manufacturing

In the pharmaceutical industry, nitrogen generators provide high-purity nitrogen essential for synthesizing and analyzing new drug compounds. They support formulation development, stability testing, and packaging. On-site nitrogen production helps you maintain stringent quality control standards while reducing operational costs.

Laboratory Applications

Nitrogen generators are indispensable in laboratories. They maintain an inert atmosphere during processes like active pharmaceutical ingredient (API) synthesis and drying. This protection prevents sensitive drugs from degradation, moisture, and oxidation. Additionally, they are crucial for sterilizing medical equipment and processing drugs.

Aerospace Industry

Fuel Tank Inerting

In aerospace, nitrogen generators serve a critical function in fuel tank inerting. By displacing oxygen, they significantly reduce the risk of combustion. This implementation acts as a crucial safety measure to avert potential accidents during flight operations.

Component Testing

Nitrogen is also utilized in component testing. It prevents oxidation during manufacturing processes like welding. This application ensures the integrity and reliability of aerospace components.

The market for nitrogen generators is expanding rapidly. The market size reached $4.8 billion in 2023 and is expected to reach $7.9 billion by 2030, with a compound annual growth rate (CAGR) of 7.3%. The rising consumer demand in the food and beverage sector drives this growth, highlighting the importance of nitrogen generator applications across various industries.

Oil and Gas Industry

Nitrogen generators play a vital role in the oil and gas industry. They enhance safety and efficiency in various operations. Here are two key applications:

Enhanced Oil Recovery

You can use nitrogen generators to boost oil recovery rates. By injecting nitrogen into oil reservoirs, you increase the pressure, which helps push more oil to the surface. This method is known as enhanced oil recovery (EOR). It allows you to extract oil that traditional methods might leave behind. The benefits of using nitrogen in EOR include:

Increased oil production.

Reduced operational costs.

Improved safety during extraction.

Nitrogen generators provide a reliable source of nitrogen for this process. They ensure that you have the necessary gas on-site, reducing the need for transportation and storage.

Pipeline Purging

Another important application of nitrogen generators is pipeline purging. You can use nitrogen to displace air or other gases from pipelines. This action minimizes the risk of explosions and enhances workplace safety. Here are some advantages of using nitrogen for pipeline purging:

Nitrogen prevents the accumulation of flammable gases.

It maintains wellbore pressure during drilling operations.

The process ensures that pipelines remain clean and free from contaminants.

Using nitrogen generators for purging pipelines helps you maintain a safe working environment. It also supports pressure testing, ensuring that your systems operate efficiently.

Choosing the Right Nitrogen Generator

Selecting the right nitrogen generator involves careful consideration of your specific needs. You must assess various factors to ensure optimal performance and efficiency. Here’s how to approach this decision:

Assessing Your Needs

Begin by evaluating your operational requirements. Consider the following aspects:

Application Type: Identify the industry and specific processes where nitrogen will be used. For example, the pharmaceutical sector often demands high-purity nitrogen for drug manufacturing.

Volume Requirements: Determine how much nitrogen you need daily. This assessment helps you choose a generator that meets your production demands without interruptions.

Factors to Consider

When choosing a nitrogen generator, keep these critical factors in mind:

Purity Requirements

Different applications require varying levels of nitrogen purity. For instance, pharmaceutical applications may need purity levels as high as 99.999%. In contrast, other industries might only require 95% purity. Assess your specific needs to select the appropriate system.

Flow Rate

The flow rate indicates how much nitrogen the generator can produce within a given time. You should measure this in standard cubic feet per minute (SCFM) or standard cubic feet per hour (SCFH). Ensure that the flow rate matches your operational needs to avoid inefficiencies.

Factor | Description |

|---|---|

Purity requirements | Varies from 95% to 99.999%, with higher purity needing more sophisticated systems. |

Flow rate | Should match consumption to avoid inefficiencies. |

Operating environment | Conditions like temperature and humidity can impact generator performance. |

Pressure requirements | Must meet the specific pressure needs of the application. |

Cost of ownership | Includes maintenance and operating costs; energy efficiency is crucial for ongoing expenses. |

By considering these factors, you can make an informed decision that aligns with your operational goals.

Nitrogen generators play a vital role in various industries. They enhance safety, reduce costs, and promote environmental sustainability. By generating nitrogen on-site, you can enjoy numerous benefits:

Evidence Type | Description |

|---|---|

Safety Improvements | Enhanced safety measures in industrial applications due to the controlled nitrogen environment. |

Cost Savings | Significant reduction in operational costs by generating nitrogen on-site rather than purchasing it. |

Environmental Benefits | Lower carbon footprint and reduced waste associated with traditional nitrogen supply methods. |

Explore your options for nitrogen generators. Seek expert advice to find the best solution for your needs. Investing in a nitrogen generator can streamline your operations and improve efficiency.

FAQ

What is a nitrogen generator?

A nitrogen generator produces nitrogen gas on-site. It eliminates the need for storage tanks or cylinders. This system provides a continuous supply of nitrogen gas, making it cost-effective and efficient for various applications.

How does a nitrogen generator improve safety?

Nitrogen generators enhance safety by creating an inert atmosphere. This atmosphere reduces the risk of combustion in industries like aerospace and oil and gas. By displacing oxygen, nitrogen gas minimizes potential hazards during operations.

What industries benefit from nitrogen generators?

Many industries benefit from nitrogen generators, including food and beverage, pharmaceuticals, aerospace, and oil and gas. Each sector uses nitrogen gas for applications like packaging, drug manufacturing, and enhancing safety in fuel tanks.

How do I choose the right nitrogen generator?

To choose the right nitrogen generator, assess your needs. Consider factors like purity requirements, flow rate, and application type. Understanding these aspects helps you select a generator that meets your operational demands effectively.

Can nitrogen generators reduce costs?

Yes, nitrogen generators can significantly reduce costs. By generating nitrogen gas on-site, you eliminate expenses related to purchasing and transporting nitrogen. This efficiency leads to lower operational costs and improved profitability.