Understanding the Operation of Nitrogen Generators

Nitrogen generators make pure nitrogen gas by extracting it from the air. To understand how do nitrogen generators work, it's essential to know that there are two main methods: Pressure Swing Adsorption (PSA) and membrane separation. Each technique employs different processes to obtain nitrogen, making them suitable for various applications. The global market for nitrogen generators is projected to grow from $8.1 billion in 2020 to $14.6 billion by 2032. Therefore, understanding these technologies is crucial for anyone considering their use.

Key Takeaways

Nitrogen generators make pure nitrogen gas from air. They use methods like Pressure Swing Adsorption (PSA) and membrane separation.

PSA systems give very pure nitrogen. This makes them great for industries like medicine and electronics. Membrane systems are easier to take care of and smaller.

Knowing the pros and cons of each nitrogen generator helps you make smart buying choices based on what you need.

The nitrogen generator market is likely to grow a lot. This shows more demand in industries like food packaging and chemical processing.

When picking a nitrogen generator, think about things like purity needs, how much gas you need, space, and budget to find the best option for you.

Overview of Nitrogen Generators

Nitrogen generators are very important in many industries. They make nitrogen gas from the air. You can find these machines in areas like chemicals, food and drink, and medicine. Each industry uses nitrogen's special qualities to create safer places and better products.

In 2020, the chemicals industry made the most money from nitrogen generators. This field needs nitrogen to safely manage dangerous processes. As you look at the market, you will see it is expected to grow a lot. By 2025, the nitrogen generator market might reach about USD 20.99 billion. It could grow at a rate of around 7.44% each year. This growth shows that more nitrogen is needed for different uses.

Here are some key industries that benefit from nitrogen generators:

Chemicals: Important for safely handling dangerous materials.

Food and Beverage: Used for packaging and keeping things fresh.

Pharmaceuticals: Helps keep products safe and effective.

The Asia-Pacific area is likely to grow the fastest during this time. This shows a growing need for nitrogen generators in new markets. If you think about buying a nitrogen generator, knowing these market trends can help you make smart choices.

How PSA Nitrogen Generators Work

Working Principle of PSA Technology

Pressure Swing Adsorption (PSA) technology is a common way to make pure nitrogen. This method separates gases. You can think of it as filtering nitrogen from the air. Here’s how it works:

Air Compression: First, a compressor pulls in air and compresses it. This makes the air pressure higher.

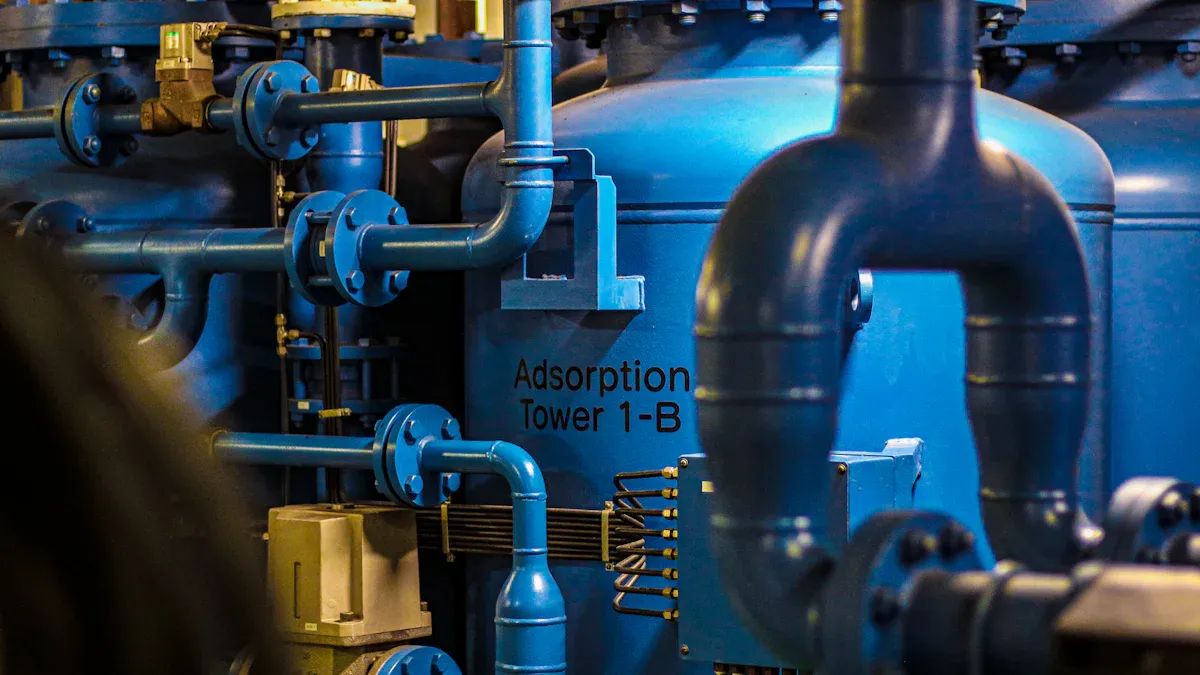

Adsorption: The compressed air goes into a tower filled with special materials, like zeolite. Under high pressure, nitrogen sticks to these materials while other gases, like oxygen and carbon dioxide, go through.

Desorption: After some time, the pressure in the tower drops. This lets the nitrogen that was stuck go free, creating pure nitrogen gas.

Cycle Repetition: The process switches between two towers. While one tower collects nitrogen, the other is releasing the gases it collected.

This cycle keeps going, giving a steady flow of nitrogen gas. How well this gas separation works depends on things like temperature, pressure, and the adsorbent used.

Key Components of PSA Systems

A PSA nitrogen generator has several important parts that work together to make nitrogen gas effectively. Here are the main parts:

Compressor: This part compresses the air, raising its pressure for the adsorption step.

Adsorption Towers: These towers hold the adsorbent material where nitrogen separation happens.

Valves: Valves control the air and nitrogen flow in the system, making sure the pressure and timing are right for each step.

Control System: This system checks and manages how the generator works, improving performance and efficiency.

These parts work together to help PSA systems produce high purity nitrogen gas.

Advantages of PSA Nitrogen Generators

PSA nitrogen generators have many benefits that make them popular in different industries:

High Purity Nitrogen: PSA systems can create nitrogen with purity levels up to 99.999%. This high purity is important for pharmaceuticals and electronics.

Cost Efficiency: By making nitrogen on-site, you depend less on outside suppliers. This can save money over time.

Energy Efficiency: New PSA systems are designed to save energy, which helps lower costs. They can also be set up in different ways for various uses.

Reliability: PSA technology is known for being reliable and performing well. With good care, these systems can work well for many years.

Here’s a quick overview of some performance metrics that show how well PSA nitrogen generators work:

Performance Metric | Description |

|---|---|

Purity | The quality of nitrogen made, showing the percentage of nitrogen in the output. |

Productivity | The amount of nitrogen made in a certain time. |

Recovery | How well nitrogen is taken from the feed air. |

Air Demand | The amount of air needed to make a certain amount of nitrogen. |

By knowing these benefits, you can understand why PSA nitrogen generators are used in many industries.

Disadvantages of PSA Nitrogen Generators

PSA nitrogen generators have many good points, but they also have some downsides. Knowing these issues helps you decide if a nitrogen generator is right for you. Here are some main disadvantages of PSA technology:

Initial Cost: Buying a PSA nitrogen generator can be expensive. You might need a big budget for the machine and setup. This cost can be hard for small businesses or new ones.

Space Requirements: PSA systems need a lot of space. You must fit in the compressor, adsorption towers, and other parts. If your place is small, this can be a problem.

Maintenance Needs: PSA nitrogen generators need regular care to work well. You have to check and change the adsorbent material often. If you skip maintenance, it can lower performance and raise costs.

Limited Output: PSA systems might not work well for jobs needing a lot of nitrogen fast. If you need big amounts of nitrogen quickly, PSA generators may not be enough.

Sensitivity to Conditions: PSA nitrogen generators can be affected by the environment. Things like temperature and humidity can change how well they work. You need to keep an eye on these factors for the best results.

Purity Variability: PSA technology can make high purity nitrogen, but the purity can change based on air quality and conditions. You might need extra steps for very high purity nitrogen.

Tip: Before buying a PSA nitrogen generator, think about your needs and see if the benefits are better than the downsides for your situation.

By knowing these downsides, you can better decide if a PSA nitrogen generator fits your needs.

How Membrane Nitrogen Generators Work

Working Principle of Membrane Technology

Membrane nitrogen generators use a special way to separate gases to make nitrogen. This method works by letting some gases pass while blocking others. Here’s how it happens:

Air Intake: The generator pulls in air from the surroundings.

Compression: The air is compressed to make it more pressurized.

Separation: The compressed air goes through membranes. These membranes have tiny holes that let smaller gases, like oxygen, go through easier than larger nitrogen molecules.

Nitrogen Collection: As oxygen and other gases pass through the membranes, nitrogen stays behind. This keeps going until you have enough nitrogen.

How well this works can change based on things like the number of membranes and the pressure used. Higher pressure can change the purity of nitrogen, while warmer air can help collect more nitrogen.

Key Components of Membrane Systems

Membrane nitrogen generators have important parts that work together for good performance. Here are the main components:

Compressor: This part compresses the air to prepare it for separation.

Membrane Modules: These modules hold the membranes that separate the gases. They are key for the purity and flow of nitrogen.

Control System: This system checks and manages how the generator works to keep it running well.

Storage Tank: After separating nitrogen, it is stored in a tank for later use.

Each part is important for how well the membrane nitrogen generator works.

Advantages of Membrane Nitrogen Generators

Membrane nitrogen generators have many benefits that make them useful for different jobs:

High Purity Levels: Many membrane systems can reach nitrogen purity levels up to 99.9995%. This is very important for fields like pharmaceuticals and electronics.

Low Maintenance: Membrane systems need little care. For example, the Infinity 1032 model shows this with its easy upkeep.

Versatility: These systems can handle different flow rates. The i-FlowLab 6XX2 model can make nitrogen at rates from 21 to 1236 liters per minute.

Compact Design: Membrane generators are usually smaller than PSA systems, making them good for places with limited space.

Here’s a quick look at some performance details for different membrane nitrogen generators:

Model | Flow Rate (L/min) | Purity (%) |

|---|---|---|

Infinity 1032 | Up to 38 | Not specified |

i-FlowLab 6XX2 | 21-1236 | Up to 99.9995 |

Solaris XE | Up to 35 | Up to 99.5 |

Infinity XE 503X | 30-390 | 95-99.5 |

By knowing these benefits, you can understand why many industries choose membrane nitrogen generators for their nitrogen needs.

Disadvantages of Membrane Nitrogen Generators

Membrane nitrogen generators have some downsides to think about before you choose this technology. They have many good points, but knowing their limits is important for making a smart choice. Here are some main disadvantages:

Performance Issues: Membrane fouling can hurt performance. This happens when tiny holes in the membranes get blocked by particles. When this occurs, the system can't separate gases well. Studies show that at 25°C, filtration stops after reducing the volume by just 6% in two hours. At higher temperatures, like 60°C, the membranes can get completely blocked, stopping nitrogen collection.

Temperature Sensitivity: Membrane systems can have trouble with temperature changes. High temperatures can cause immediate plugging, which stops the system from working. You need to watch the operating conditions closely to keep things running well.

Limited Lifespan: The lifespan of membranes can be shorter than you think. Over time, fouling and wear can make them less effective. You might need to change membranes more often than with other technologies.

Lower Purity Levels: While membrane systems can reach high purity levels, they might not always meet strict needs in some industries. If you need ultra-pure nitrogen, you may find that membrane generators do not compare well to PSA systems.

Higher Operating Costs: Even though membrane systems need less maintenance, they can have higher operating costs over time. Frequent membrane replacements and possible lower efficiency can add up.

Tip: Before buying a membrane nitrogen generator, think about these downsides in relation to your needs. Consider things like required purity levels, operating conditions, and budget limits.

By knowing these downsides, you can better decide if a membrane nitrogen generator is the right choice for you.

Comparing PSA and Membrane Technologies

Purity Levels of Nitrogen Produced

When you look at PSA and membrane nitrogen generators, purity levels are very important. PSA systems can make high purity nitrogen with levels from 95% to 99.999%. This is great for industries needing strict purity, like pharmaceuticals and electronics. On the other hand, membrane systems usually reach nitrogen purity levels between 95% and 98%. They can get higher purities with more air, but they don't usually match PSA technology's best levels.

Technology | Purity Range |

|---|---|

PSA | 95% to 99.999% |

Membrane |

Maintenance Requirements

Maintenance is another key point to think about. PSA nitrogen generators need regular checks and care, but ordinary technicians can usually do these tasks. The maintenance is not too hard, so most places can manage it. In contrast, membrane systems need very little maintenance. You just have to do simple upkeep on the membrane parts and purification equipment. This easy maintenance can be a big plus for smaller businesses or those with fewer technical workers.

Reliability and Efficiency

Both technologies are reliable and efficient, but they work differently. PSA systems use advanced control systems and backup parts to improve reliability. They keep a steady nitrogen supply by switching between adsorption and depressurization. This method helps them perform well, even when conditions change.

For cost-effectiveness, PSA systems are cheaper than buying bulk gas. They can produce nitrogen at high purity levels, making them a good choice for tough applications. Membrane systems usually use less electricity than cryogenic distillation, but they might not always give the same purity level.

System Type | Purity Level | Cost-Effectiveness |

|---|---|---|

PSA | Less costly than bulk gas | |

Membrane | Up to 99% | Typically lower electricity use than cryogenic distillation |

Common Questions About Nitrogen Generators

How to Choose the Right Nitrogen Generator?

Picking the right nitrogen generator depends on what you need. Start by thinking about these things:

Purity Requirements: Find out how pure you need the nitrogen for your work. PSA systems can make purer nitrogen than membrane systems.

Production Rate: Think about how much nitrogen you will need. Some systems can make more nitrogen than others.

Space Availability: Check how much space you have for the machine. Membrane systems are usually smaller than PSA systems.

Budget: Consider both the starting costs and the costs to run it later. Making nitrogen on-site can save you money in the long run.

What Applications Benefit from Nitrogen Generators?

Nitrogen generators help many industries. Here are some uses that gain a lot:

Food Packaging: Nitrogen keeps food fresh and makes it last longer.

Pharmaceuticals: Pure nitrogen helps keep products safe and working well.

Electronics Manufacturing: Nitrogen stops oxidation during making products.

Chemical Processing: Nitrogen creates a safe environment for sensitive reactions.

How Long Do Nitrogen Generators Last?

The life of nitrogen generators can change based on the type. Here’s what to expect:

Membrane Separation Technology: Membranes can last up to 20 years if used all the time. Replacement costs are low, usually about 25% of the generator's price.

Pressure Swing Adsorption (PSA): Makers say these can last over 20 years with good care. But, changing parts might need special workers.

Knowing these points can help you make smart choices about nitrogen production for your needs.

Nitrogen generators are very important in many industries. They are used for things like food packaging, medicine, and chemical processing. Knowing how nitrogen generators work helps you make smart choices. PSA systems give very pure nitrogen. Membrane systems are easier to take care of. Think about these points carefully to pick the best nitrogen generator for you.

FAQ

What do nitrogen generators do?

Nitrogen generators make nitrogen gas from the air. This nitrogen can be used for many things, like food packaging, medicine, and chemical work.

How do I pick the right nitrogen generator?

Think about how pure you need the nitrogen, how much you need, how much space you have, and your budget. Look at these things to find the best generator for you.

Can nitrogen generators run all the time?

Yes, many nitrogen generators can run all the time. But, you should check how they are doing and keep up with maintenance to make sure they work well.

What kind of maintenance do nitrogen generators need?

Nitrogen generators need regular checks and care. For PSA systems, you need to change the adsorbent materials. Membrane systems need less care but still need checks now and then.

How fast can nitrogen generators make nitrogen?

How fast they produce nitrogen depends on the model and type. PSA systems usually make nitrogen at a steady speed, while membrane systems can produce more quickly, based on their design.