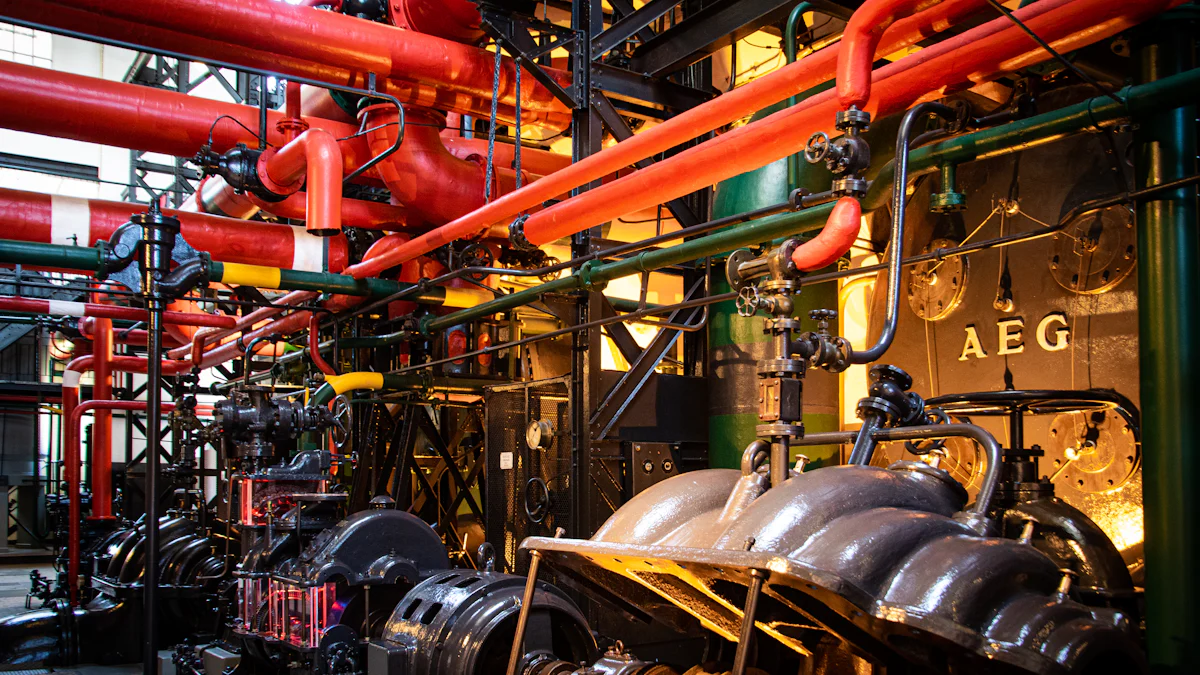

What is a Pressure Vessel and Why It Matters

A pressure vessel is a container designed to hold gases or liquids at a pressure substantially different from the ambient pressure. You will find pressure vessels in many industries, including oil and gas, chemical manufacturing, and power generation. The global pressure vessels market was valued at USD 60.24 billion in 2024, with significant growth expected in the coming years. Safety and maintenance are crucial for these vessels. Regular inspections and adherence to safety standards help prevent accidents and ensure efficient operation.

Key Takeaways

Pressure vessels are containers for gases or liquids under high pressure. They are important in industries like oil, gas, chemicals, and power.

Regular checks and care for pressure vessels are very important. These actions help stop accidents and keep operations safe.

Different kinds of pressure vessels have special jobs. Storage vessels keep materials, process vessels help chemical reactions, and heat exchangers move heat well.

Safety rules, like the ASME Boiler and Pressure Vessel Code, help design and care for pressure vessels. Following these rules keeps people and equipment safe.

Ignoring maintenance can cause big accidents and money loss. Regular checks and preventive steps are key for safe operations.

Types of Pressure Vessels

Pressure vessels come in various types, each serving specific functions in different industries. Understanding these types helps you appreciate their roles in safety and efficiency.

Storage Vessels

Storage vessels are essential for holding liquids and gases in industrial settings. You often find them storing materials like natural gas, liquid nitrogen, and petroleum products. These vessels typically use carbon steel for construction, which provides durability and strength. Additionally, many storage vessels feature internal liners made from various materials. These liners protect the vessel from the stored product, ensuring compatibility and cost-effective construction.

Process Vessels

Process vessels facilitate various industrial processes, such as mixing, separating, and chemical reactions. You will see them in applications like food and beverage processing, oil and gas processing, and plastics processing. For instance, in food and beverage processing, pressure vessels purify water and carbonate drinks. They heat water to create vapor, which condenses back into liquid, ensuring safe and clean water.

Heat Exchangers

Heat exchangers play a crucial role in transferring heat between fluids without direct contact. You can find them in industries like food, pharmaceuticals, and energy. These devices rely on the thermal and flow properties of the fluids involved. The materials used in heat exchangers must withstand stresses from temperature differences and internal pressure. This ensures efficient operation and safety in various applications.

Reactors

Reactors are specialized pressure vessels designed to facilitate chemical reactions under controlled conditions. You will find them in industries such as pharmaceuticals, petrochemicals, and food processing. These vessels allow you to manage temperature, pressure, and reaction time effectively, ensuring optimal production.

When considering reactor safety, several factors come into play. Here are some key safety considerations specific to reactors:

Refer to existing in-house guidance.

Understand construction limitations.

Assess links in the structure.

Evaluate vessel capacity.

Know the temperature and pressure rating.

Prioritize maintenance.

Manage by-products and loss of control.

Consider scale-up processes.

Ensure external safety measures.

Conduct reality checks on operational parameters.

Regular inspection and maintenance of reactors are crucial. These practices not only comply with regulatory requirements but also prevent catastrophic failures. The ASME Boiler and Pressure Vessel Code, along with NBIC standards, provides essential guidelines for the design, construction, and maintenance of reactors. Following these guidelines ensures safe operation and protects both personnel and assets.

Applications of Pressure Vessels

Pressure vessels play a vital role in several industries, ensuring safe and efficient operations. Their applications span across various sectors, including oil and gas, chemical manufacturing, and power generation.

Oil and Gas Industry

In the oil and gas industry, pressure vessels are crucial for storing and processing hydrocarbons. They help you manage high-pressure gases and liquids safely. These vessels are essential for:

Compressing and storing natural gas.

Refining crude oil.

Transporting volatile compounds.

You can find pressure vessels in refineries, where they facilitate the separation and purification of different oil fractions. Their design ensures that they withstand extreme conditions, making them indispensable in this sector.

Chemical Manufacturing

Pressure vessels are integral to chemical manufacturing processes. They allow you to control chemical reactions under specific pressure conditions. Common applications include:

Food and beverage processing: Here, pressure vessels purify water and carbonate beverages.

Oil and gas processing: They compress, store, and refine gases.

Plastics processing: These vessels store natural gas and other volatile compounds under pressure.

In each of these applications, the design of pressure vessels ensures safety and efficiency, allowing for optimal production and minimal risk.

Power Generation

In power generation, pressure vessels, particularly boilers, are essential. They produce high-pressure steam through the combustion of fossil fuels. This steam drives turbines, generating electricity. Notably, boilers are projected to account for 40.3% of the market share in 2024. Pressure vessels also play a role in:

Facilitating efficient energy production in steam turbines.

Supporting various engineering applications, making them a cornerstone of modern infrastructure.

By understanding these applications, you can appreciate the significance of pressure vessels in maintaining safety and efficiency across multiple industries.

Food and Beverage Processing

In the food and beverage industry, pressure vessels play a vital role in ensuring safety and quality. You will find these vessels used in various processes, from pasteurization to carbonation. Their ability to handle high pressures makes them essential for several applications.

One significant use of pressure vessels is in high-pressure treatment. This method aids in pasteurization and commercial sterilization. By applying high pressure, you can effectively kill harmful bacteria without compromising the food's quality. This process also helps with:

Meat tenderization

Protein denaturation

Nutrient infusion

Lipid crystallization

These benefits enhance the overall quality of food products, making them safer and more appealing to consumers.

Pressure vessels also contribute to water purification. They heat water to create vapor, which then condenses to remove contaminants. This process ensures that the water used in food production meets safety standards.

In carbonated beverage production, pressure vessels are crucial. They dissolve carbon dioxide gas into sodas and sparkling water, creating that signature fizz. Without these vessels, you would struggle to achieve the desired carbonation levels.

Tip: When selecting pressure vessels for food and beverage applications, consider factors such as material compatibility, pressure ratings, and maintenance requirements. Proper selection ensures safety and efficiency in your operations.

Overall, pressure vessels are indispensable in the food and beverage sector. They help maintain product quality, enhance safety, and improve processing efficiency. Understanding their applications allows you to appreciate their importance in delivering safe and enjoyable food and drink products to consumers.

Safety Standards and Regulations for Pressure Vessels

Safety standards and regulations play a crucial role in ensuring the safe operation of pressure vessels. You must understand these guidelines to protect both personnel and equipment.

ASME Boiler and Pressure Vessel Code

The ASME Boiler and Pressure Vessel Code (BPVC) sets the standard for the design, construction, and maintenance of pressure vessels. This code includes several key components that you should be aware of:

ASME BPVC Section I - Rules for Construction of Power Boilers

ASME BPVC Section II - Materials

Part A - Ferrous Material Specifications

Part B - Nonferrous Material Specifications

Part C - Specifications for Welding Rods, Electrodes, and Filler Metals

Part D - Properties (Customary)

Part D - Properties (Metric)

ASME BPVC Section VIII - Rules for Construction of Pressure Vessels

ASME BPVC Section IX - Qualification Standard for Welding, Brazing, and Fusing Procedures

These sections provide detailed guidelines that help you ensure the safety and reliability of pressure vessels in various applications.

OSHA Regulations

The Occupational Safety and Health Administration (OSHA) also establishes regulations that pertain to pressure vessels. Here are some specific requirements you need to follow:

Regulation Category | Specific Requirements |

|---|---|

Hazardous Materials | Keep compressed gas cylinders in a visibly safe condition. |

| | Follow Compressed Gas Association Pamphlets for storage and handling. | | | Install and maintain pressure relief devices for all compressed gas cylinders. | | Compliance Testing | Ensure pressure vessels undergo testing to comply with ASME BPVC requirements. | | DOT Specifications | Some vessels may need to adhere to DOT specifications and regulations. |

These regulations help you maintain a safe working environment and prevent accidents related to pressure vessels.

Industry-Specific Standards

In addition to ASME and OSHA, various industry-specific standards exist. These standards provide additional guidelines tailored to specific sectors. Some examples include:

API Standards: Provided by the American Petroleum Institute, these standards guide the structural integrity of pressure vessels.

OSHA Technical Manual (OTM): Offers detailed information on safety and hazard evaluations of pressure vessels.

API 579 Fitness For Service: Provides guidelines for evaluating the structural integrity of pressure vessels.

By adhering to these standards, you can enhance the safety and efficiency of your operations involving pressure vessels.

Importance of Proper Maintenance of Pressure Vessels

Proper maintenance of pressure vessels is crucial for ensuring safety and efficiency in various industries. Regular inspections and preventive maintenance practices help you identify potential issues before they escalate into serious problems.

Regular Inspections

You should conduct regular inspections of pressure vessels to maintain their integrity. Here are some recommended frequencies for these inspections:

External visual inspections should occur every five years unless a Risk-Based Inspection (RBI) justifies a different schedule.

Internal inspections should take place at least every ten years or at half the remaining useful life of the vessel, whichever is less.

If the remaining safe operating life is less than four years, you may need to inspect the vessel every two years.

Operating conditions can also affect inspection frequency. For example, vessels under harsh conditions may require more frequent checks. Compliance with regulations is essential, as some dictate specific inspection intervals. A risk assessment approach can help determine how often you need to inspect high-risk vessels.

Preventive Maintenance Practices

Implementing preventive maintenance practices can significantly extend the life of your pressure vessels. Here are some best practices to follow:

Conduct regular visual inspections to spot signs of corrosion, leakage, or deformation.

Perform thorough risk assessments to identify potential hazards.

Use non-destructive testing techniques to detect internal flaws.

Regularly measure the thickness of the vessel's walls to monitor corrosion.

Implement corrosion prevention measures to protect the vessel.

Ensure pressure relief devices are functional and tested regularly.

Maintain detailed records of inspections, tests, and repairs.

Comply with relevant codes and standards.

Have qualified personnel carry out repairs and verify integrity post-repair.

By following these practices, you can ensure the quality testing and inspection of pressure vessels, which is vital for safe operations.

Consequences of Neglect

Neglecting maintenance can lead to severe consequences. You risk catastrophic failures, which can result in injuries, fatalities, and significant financial losses. Additionally, regulatory penalties may arise from non-compliance with safety standards. Regular maintenance and inspections are not just best practices; they are essential for protecting lives and assets.

Pressure vessels are specialized containers that hold gases or liquids at pressures significantly different from the surrounding environment. They play a crucial role in ensuring safe containment and management of high-pressure substances across multiple industries. You can find pressure vessels in sectors such as oil and gas, power generation, and chemical manufacturing. Their importance cannot be overstated.

To summarize, pressure vessels are essential for maintaining safety and compliance in industrial operations. They meet specific safety standards and legal requirements, which help prevent accidents and ensure operational efficiency. By understanding their types, applications, and maintenance needs, you can appreciate how pressure vessels contribute to safety and efficiency in your industry.

FAQ

What materials are commonly used to construct pressure vessels?

You typically find pressure vessels made from carbon steel, stainless steel, and alloy materials. These materials provide strength and durability, ensuring the vessel can withstand high pressures and temperatures.

How often should I inspect a pressure vessel?

You should inspect pressure vessels regularly. External inspections should occur every five years, while internal inspections should happen at least every ten years or based on the vessel's remaining useful life.

What are the risks of neglecting pressure vessel maintenance?

Neglecting maintenance can lead to catastrophic failures, injuries, and significant financial losses. You may also face regulatory penalties for non-compliance with safety standards.

How do pressure relief devices work?

Pressure relief devices automatically release excess pressure from a vessel. They prevent over-pressurization, ensuring safe operation. Regular testing of these devices is crucial to maintain their effectiveness.

What is the ASME Boiler and Pressure Vessel Code?

The ASME Boiler and Pressure Vessel Code sets safety standards for the design, construction, and maintenance of pressure vessels. Following this code helps ensure safe operation and compliance with regulations.